CONTENTS

Trending searches

Carrello ($0)

Carrello ($0)

ABSTRACT

In laser cutting, precision and cut quality are crucial. The overcut technique is an effective way to improve cutting results, ensuring smoother edges and cleaner finishes. This guide will walk you through what overcut is, why it’s useful, and how to set it up in LightBurn to achieve optimal cutting performance.

1. What is Overcut?

Overcut refers to extending the laser’s path slightly beyond the actual endpoint of a shape during cutting. This ensures the material is completely severed — especially important for thicker or harder materials — and helps reduce edge imperfections such as burrs or uneven lines.

2.Why Use Overcut?

a) Improves edge quality:

Overcutting reduces burrs and results in cleaner, smoother cut edges.

b) Ensures full penetration:

On thicker materials, overcut guarantees that the laser beam cuts all the way through.

c) Enhances part fit and accuracy:

For intricate designs, a slight overcut can help parts fit better by eliminating incomplete cuts or undercuts.

3. How to Set Up Overcut in LightBurn

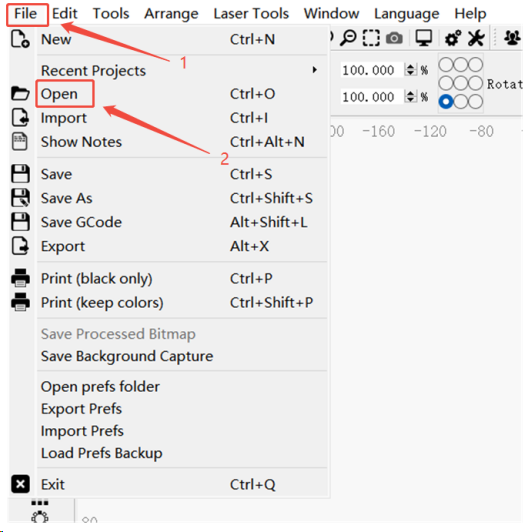

Step 1: Launch LightBurn

Open the LightBurn software. From the “File” menu, select “Import” to bring in your design file. Make sure your design is displayed correctly on the canvas.

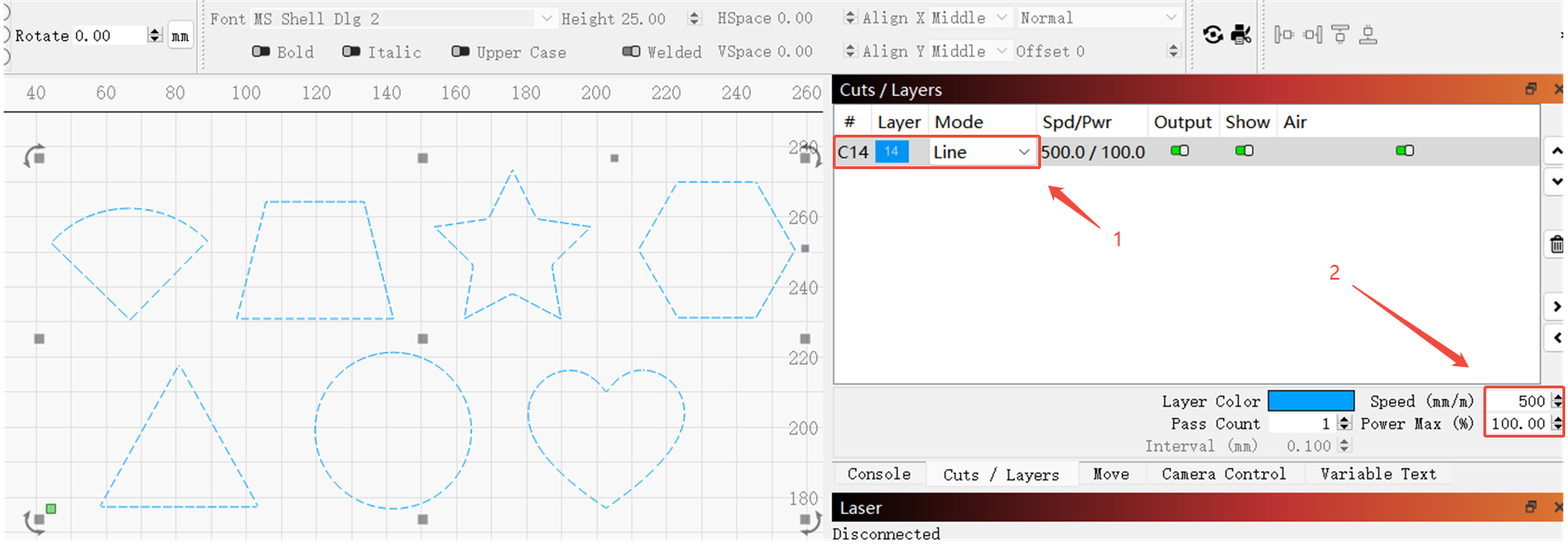

Step 2: Select the Object to Apply Overcut

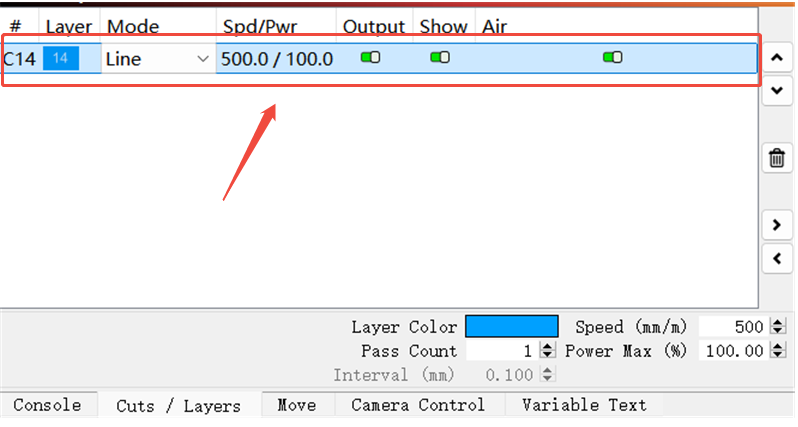

On the canvas, select the object you want to cut. In the "Cuts/Layers" panel on the right, select the layer you wish to modify.

Make sure the cut mode is set to "Line", and adjust the speed and power settings as needed.

Step 3: Configure the Overcut Settings

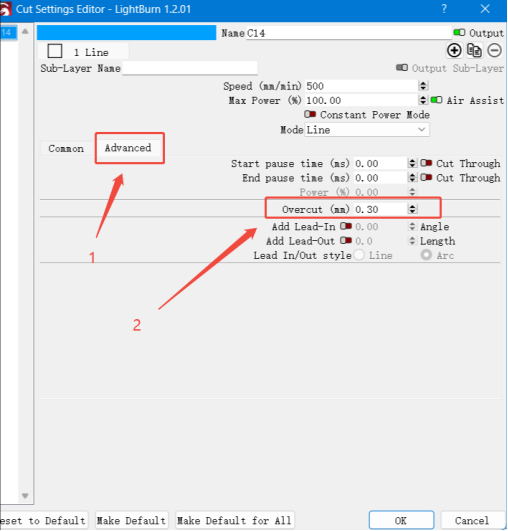

Click on the colored box of the selected layer to open the Cut Settings Editor.

In the Cut Settings Editor, go to the Advanced tab and locate the Overcut option.

Input the overcut distance: Depending on the material type and thickness, enter an appropriate value — typically between 0.1 mm and 2 mm. Adjust as necessary based on your testing and material response.

Step 4: Save and Start Cutting

Once all settings are configured, save your project and send the job to your laser machine.

Ensure that the laser's power and speed settings align with the overcut value to avoid incomplete cuts or overheating.

4. Tips & Recommendations

a) Understand your material:

Different materials respond differently to overcutting. You may need to fine-tune the value based on the material's properties.

b) Match power and speed:

Make sure the laser’s speed and power are properly balanced to complement the overcut distance.

c) Run a test cut:

Always perform a small-scale test before starting a full job. This helps you validate the overcut effect and fine-tune your settings.

Conclusion

Using the Overcut feature in LightBurn is a simple yet powerful way to enhance your laser cutting results. By slightly extending the cut path, you can ensure full material penetration, reduce edge imperfections, and improve overall precision—especially on thicker or more challenging materials. With just a few adjustments in the Cut Settings Editor, you can take your projects to a more professional level. Always test and fine-tune your settings for best results, and let your creativity shine with cleaner, sharper cuts every time.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!