CONTENTS

Trending searches

Popular products

Cart ($0)

Cart ($0)

ABSTRACT

In laser engraving and cutting, properly using rotary attachments such as chucks and rollers is essential for working with rotationally symmetrical objects. As a powerful laser control software, LightBurn offers various functions to help users work efficiently. This guide explains how to quickly and accurately enable the rotary mode in LightBurn to optimize the use of chucks and rollers.

1. What Is Rotary Mode

The rotary function in LightBurn allows users to rotate design graphics at specific angles to accommodate materials of different shapes and sizes. This function is especially useful when using roller or chuck-style attachments, enabling engraving or cutting on cylindrical or irregularly shaped objects.

2. Connecting the Rotary Attachment

a) Disconnect the Y-axis motor cable from the laser machine and connect it to the chuck or roller.

If the motor jitters or does not rotate properly, it may be due to mismatched wiring in the extension cable. Try using another adapter cable with a different wire sequence.

b) Turn on the machine and confirm that the laser engraver is properly connected to the computer. Make sure the correct COM port and device profile are selected in LightBurn.

c) Load the material:

Adjust the roller spacing or chuck diameter according to the diameter of the material. Place the object securely on the chuck or roller and manually rotate it to ensure the object is stable and does not wobble.

d) Adjust the focus:

Move the laser head to the top surface of the material. Use a focusing tool to align the laser’s focal point precisely with the top of the material.

3. Configuring Rotary Parameters

To enable rotary mode quickly and accurately, follow these steps:

a) Select the design: On the LightBurn canvas, select the design you want to rotate or import the file you plan to engrave.

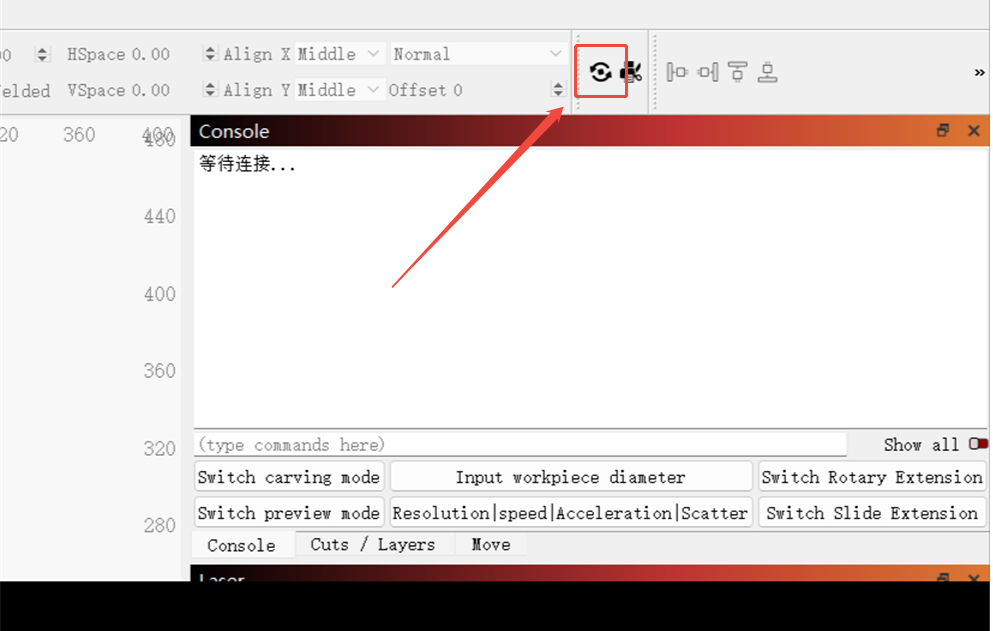

b) Access the rotary tool settings:

Click the Rotary Setup icon on the toolbar to enter the rotary configuration panel. Using the roller-type rotary as an example, follow these steps:

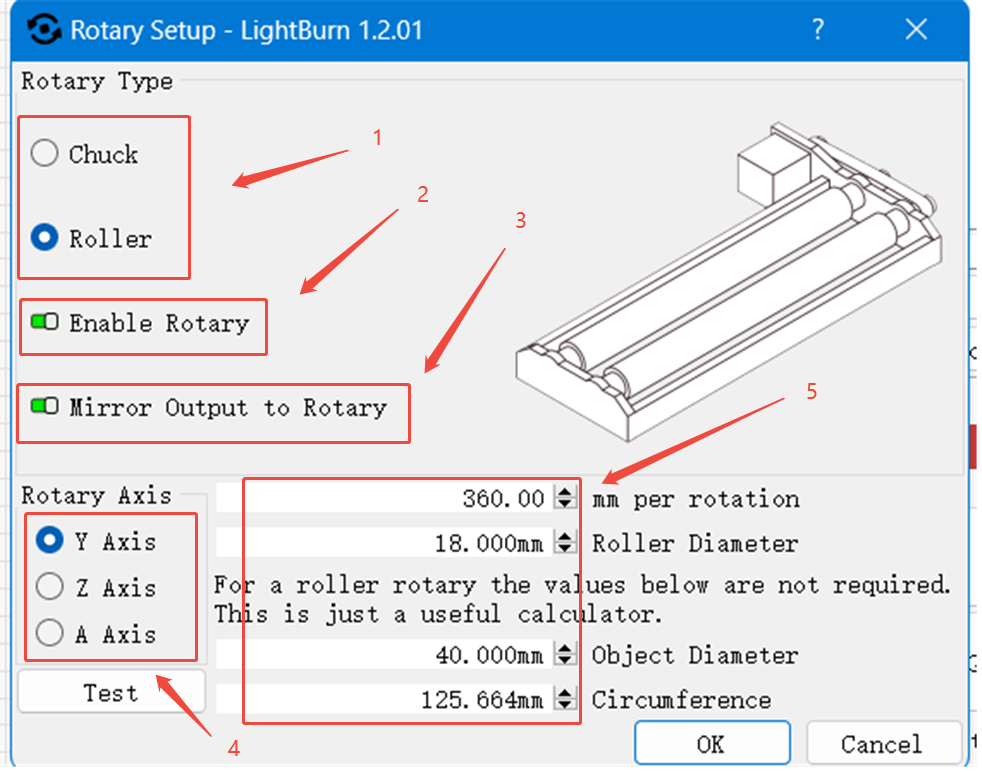

1. Choose Rotary Tool Type

In the Rotary Type section, select the type of rotary tool based on your hardware:

Roller (cylindrical rollers)

Chuck (rotating clamps)

2. Enable or Disable Rotary Function

Check the "Enable Rotary" option to turn on rotary support. If the rotary is not needed, uncheck this option to disable it.

3. Enable Mirror Output (Optional)

Check "Mirror Output to Rotary" to enable mirrored engraving. This is useful for certain design requirements.

4. Select the Rotary Axis

Assign the rotation to the correct motor axis. Typically, the Y-axis is used as the rotary axis.

5. Set Rotary Parameters

Steps per rotation: Input the number of motor steps required for one full rotation. This ensures accurate control of the rotary motion.

Roller diameter: Enter the diameter of the roller. This allows the software to calculate movement distances correctly.

Object diameter: Enter the diameter of the item being engraved.

Circumference: Once the object diameter is entered, LightBurn will automatically calculate the circumference. No manual input is needed.

4. Test the Engravin

After setting the parameters, it is recommended to run a test engraving first. Verify that the engraving result is as expected before starting the final job.

Let me know if you want this optimized for beginners, made more concise for a quick-start guide, or turned into a printable instruction sheet (PDF, flyer, etc.).

Conclusion

Properly enabling and configuring rotary mode in LightBurn is essential for achieving precise and stable engraving on cylindrical or symmetrical objects. By following the correct steps to connect your rotary attachment, set up the appropriate parameters, and perform a test run, you can significantly improve the quality and accuracy of your rotary engravings. Whether you're using a roller or chuck-style device, LightBurn provides the flexibility and control needed to handle a wide range of materials and designs with confidence.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!