Products

Trending searches

Popular products

Cart ($0)

Cart ($0)

Safety Precautions:

Main safety considerations include laser eye protection, appropriate clothing, and working in a well-ventilated area. Ensure that you wear appropriate PPE, wear appropriate laser safety eyewear that matches the laser's wavelength and optical density to guard your eyes from the laser source. The work area should be well-ventilated so that the smoke and fumes do not haze up the entire area. Implement all cautions that are recommended by LONGER. The necessity of laser safety rules cannot be emphasized enough – to avoid the risks which are tied to laser devices. These practices include but are not limited to: paying attention to all steps involved in the operation of the laser device, taking extra care with it, and performing regular checks. This is of great importance along with following all applicable security and safety rules.

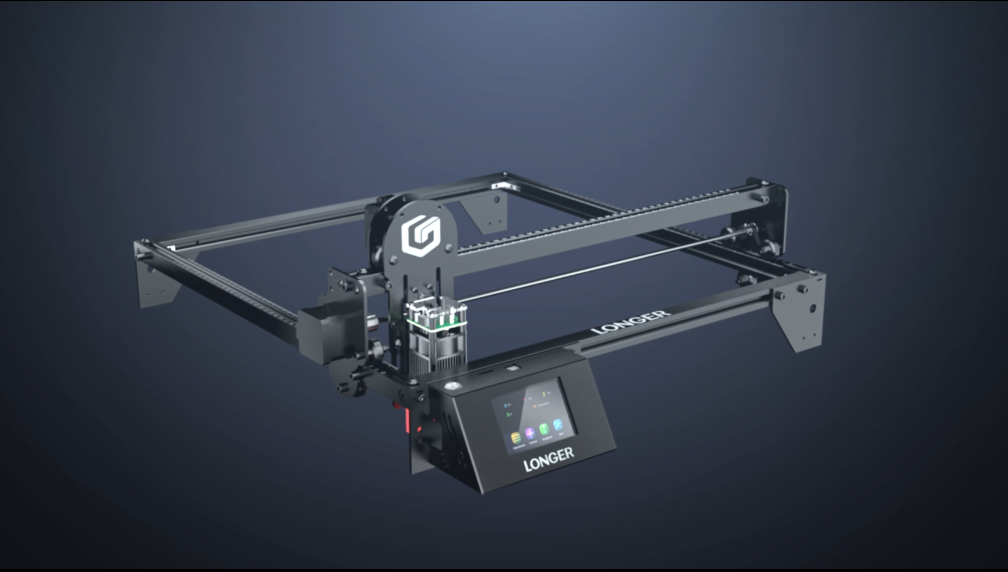

Laser Cutting:

The next step is to conduct the setup, material preparation, and calibration once everything is ready. You then proceed to commence the laser-cutting process. Place the design file into the computer software or the machine's controller, and be sure to mull over the settings and parameters. Do not forget to watch the machine during the process of its operation. Selecting the right materials is crucial for successful laser engraving. Consider safety issues and potential hazards associated with the materials chosen for experimentation.

Design File Preparation:

Preparing the design file is the next step in the laser engraving process. Generate or import the design file in .dwg or .dxf format, ensuring that it accurately reflects the desired shape, size, and cutting paths. Organize the design file by filing the paper material with several colors or placing them on different layers, facilitating easier processing and organization during laser engraving. Load the design file into the software or controller of the laser work machine, ensuring compatibility and accuracy and let calibration and focus are perfect. Whether you are working on a large-scale project or a small, intricate design, having the best engraver setup and a properly prepared design file is critical. This is especially true for tasks like glass engraving or when using a laser engraver for wood, where precision and detail are paramount.

Test and Adjust:

Before proceeding with full-scale engraving, it's advisable to perform a test cut on a limited portion of the material using product. This allows for adjustments to be made to cutting configurations if necessary, ensuring that the final engraving meets the desired specifications and quality standards. With the machine properly set up and calibrated, proceed to install the substrate inside the lasing machine operating space. Activate the laser cutter and initiate the cutting process, ensuring continuous and proper removal of material. Monitor the cutting application closely to ensure accuracy and consistency throughout the process. Testing and adjusting are crucial, especially when working with new or unfamiliar materials. For instance, if you’re operating a laser engraver for wood or stone engraving, initial test runs can help fine-tune the settings to avoid damaging the material or the machine.

Post-Cutting Finishing:

Once the laser cutting is complete, carefully remove the cut pieces from the cutting bed, taking care to avoid sharp edges. Depending on the material and intended use, additional finishing steps such as sanding, painting, or assembling may be necessary to achieve the desired final product. Follow the steps for ultra-simple finishing for LONGER Laser Engraver operation, including cleaning, surface treatment, color filling, polishing, protective coating, and quality checking to ensure the finished product meets specific requirements and standards. For specialized projects, such as using an engraving machine for jewelry, the post-cutting finishing process might involve more detailed and delicate steps to ensure the final product’s quality and aesthetic appeal. Utilizing resources from a little machine shop store can provide additional tools and materials needed for these finishing touches.

Remember to consult the operation manual from LONGER and adhere to the recommended procedures for operating LONGER laser cutting equipment to ensure safe and efficient operation.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!