Introduction

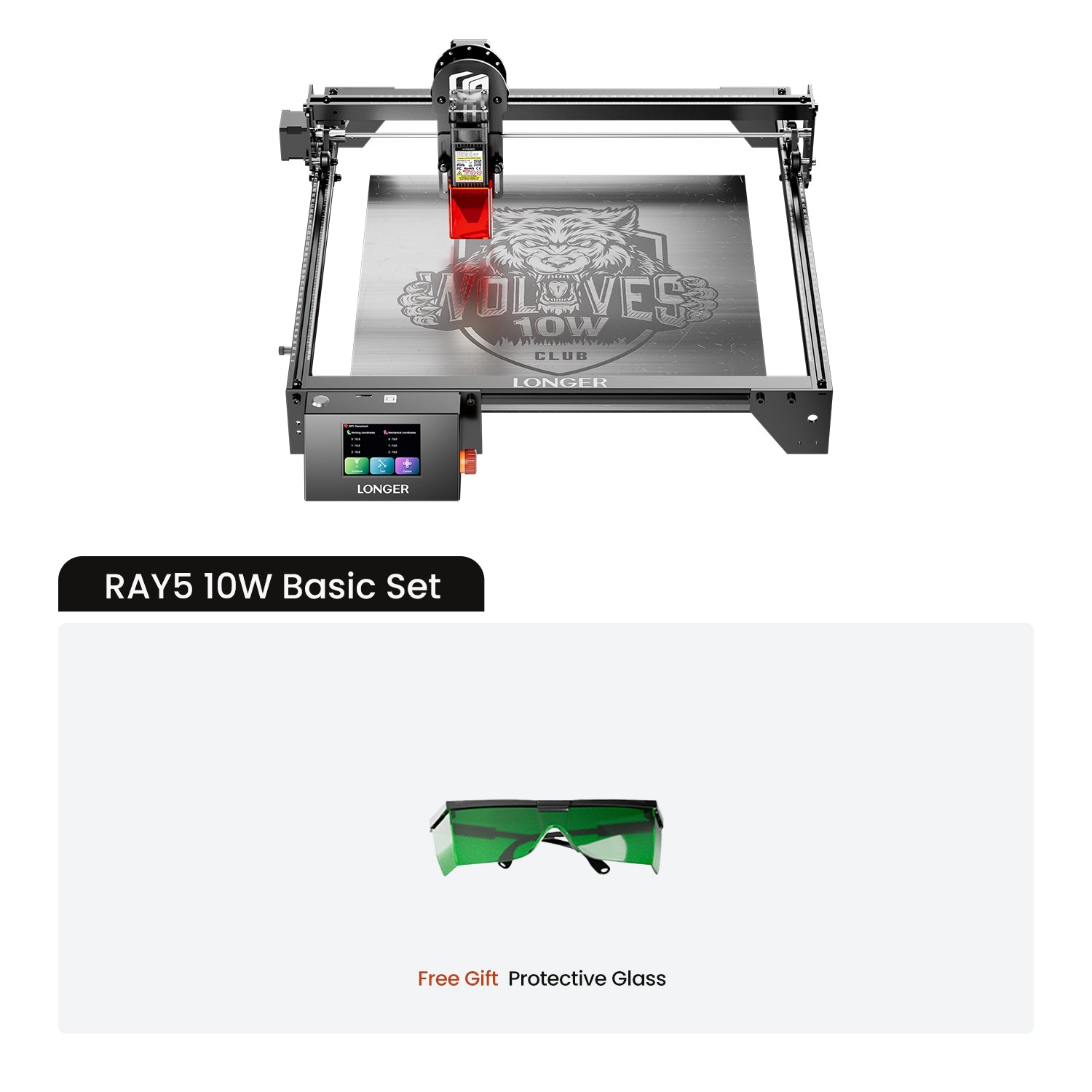

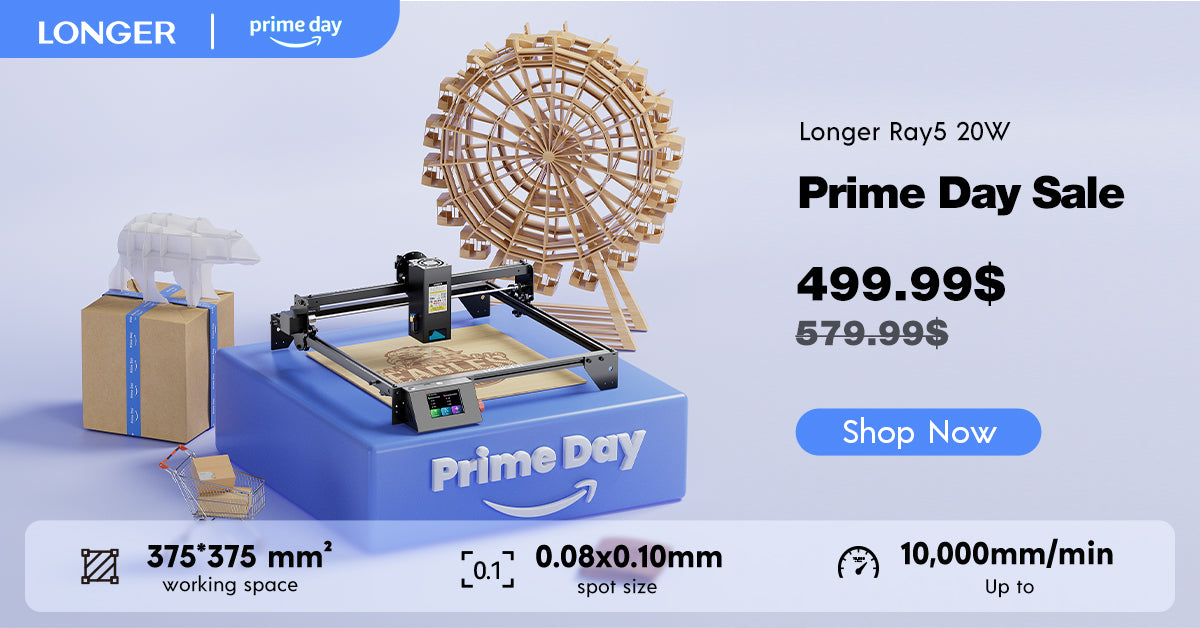

The Ray5 10W laser engraver, featuring Dioser Technology, boasts a working area of 400x400mm (15.75x15.75 inches) and a laser wavelength of 450nm. With a fixed focal length of 50mm and a laser spot size of 0.06x0.06mm, it offers exceptional precision. The 10W optical output power ensures efficient engraving and cutting, with a maximum consumption of 60W. The engraver can cut up to 20mm basswood and 30mm acrylic, making it versatile for various applications. The fastest working speed of 10000mm/min and compatibility with multiple operating systems and devices further enhance its functionality.

One of the primary benefits of laser engraving in the food industry is its ability to create intricate and precise designs on food products. This technology allows for the customization of food items, making them unique and visually appealing. For instance, laser engraving can be used to add designs or messages on chocolate, biscuits, and cakes, enhancing their aesthetic value and appeal to consumers.

Laser engraving also plays a crucial role in food packaging. It allows for the engraving of barcodes, expiry dates, and other important information directly onto the packaging material. This makes the information permanent and resistant to fading or peeling, unlike traditional ink or labels. Engraving on plastics, glasses, papers, and other materials ensures the longevity and clarity of the information.

The future of laser engraving in the food industry is promising. Potential developments include laser pretreatment to improve adhesion properties, microbial deactivation to minimize foodborne diseases, and laser-assisted cooking to enhance the taste, texture, and nutritional value of food. These advancements will add significant value to food processing, packaging, and testing.

Laser engraving on fruits and vegetable

Laser engraving on fruits and vegetables creates natural stickers, eliminating the need for traditional packaging materials. This process is environmentally friendly, reducing plastic waste and offering a non-toxic alternative. Laser marking on food is energy-efficient, quick, and hygienic, allowing for complex patterns and high throughput. It ensures product legitimacy and quality by eliminating the use of plastic, paper, or glue.

Laser ablation clean

Laser ablation, a process that removes material from the surface of food, can be used for cleaning, decontamination, or designing patterns on food products. This non-destructive testing method helps in maintaining the quality and composition of food items. Trends in laser engraving technology are continually evolving, benefiting the food industry in terms of precision, speed, and safety.

Examples of laser engraving applications in the food industry include natural branding, food packaging, customized food products, and personalized packaging. Natural branding involves marking fruits, vegetables, and other food products with barcodes, serial numbers, and expiry dates without affecting their taste, shelf life, or aroma. This technique is suitable for various food items, including apples, bananas, bread, cucumbers, and avocados.

Food packaging

Laser engraving on food packaging materials, such as plastics, glasses, and papers, ensures that important information remains intact and legible. Customized food products, like chocolates, biscuits, and cakes, can be engraved with intricate designs or messages, making them unique and appealing to consumers. Personalized packaging allows for the addition of names, messages, or logos on food packages, making them ideal for gift items like wine bottles, cheese platters, and food baskets.

In conclusion, owning a laser engraver like the Ray5 10W offers significant advantages in the food industry. Its precision, versatility, and eco-friendly nature make it an invaluable tool for food producers. The ability to create intricate designs, ensure product quality, and reduce environmental impact highlights the importance of laser engraving technology in modern food production and packaging.