Laser engraving is famous in the art and industry. These versatile tools have revolutionized in the woodworking and mark making on the various materials. The laser engraving technology has changed crafts due to versatility and efficiency of its operations. These gadgets come from power 5W to 40W for varied purpose. The detailing purpose is served by the 20W laser engraver, where the 40W laser cutter breezily cuts through materials. Laser enclosures are involved in working with safety measures. From crafts to markings and personalized gifts, laser engraving equipment is versatile. RAY5 in 10W and 5W are longer versions of bringing power and accuracy to RAY5. With improving technology, with time, laser engraving equipment will advance expressiveness and operations. This article talked about the technology that defines engraving using a laser, its intricated uses, and hints of future possibilities.

How Does a Laser Engraving Machine Work?

The light is employed to cut or alternatively each other materials. Various applications for these machines are involved with woodworking, sign manufacturing, and product customizing among others. The best laser cutting machine is made by components. The light for laser engraving could be provided either by CO2 lasers or fiber lasering. When such focussed laser hits the material, it would either burn or undergo the process of controlled ablation. Machines for engraving and cutting employ laser beams guided by computers. Engraving depth and complexity depend on laser intensity, speed, as well as focus. Laser engraving equipment can imprint various patterns on wood, metal, plastics, and textiles, thus being applicable in crafts and manufacturing.

Key Components of a Laser Engraving Machine

Laser Source

For the wavelength of CO2 lasers, it is absorbed by wood and acrylic and therefore they are the most preferred for engraving. In the case of engraving metal and plastics, fiber lasers are the best since they give high accuracy.

Laser Head

Flexibility of laser head is key to precise focus and depth of engraving. Function ensures that laser performance is optimized in view of material parameters to refine precision and well detailed results.

Controller

The controller does the control of motions of a laser head, analysis of complex computer design data. The data is translated into particular instructions of the lasers that are precise to permit the machine to exactly do a recreation of complicated patterns.

Motion System

The motion system has precise motors and mechanical elements. The belts, pulleys, and gears of the X, Y, and Z axes are designed to allow smooth and accurate motions that significantly affect engraving quality.

Work Bed/Table

The material bed adjusts according to the thickness of materials engraved. Rotary attachments enhance the laser's engraving of round or cylindrical items like bottles and trophies.

Cooling System

Laser sources produce a considerable amount of heat when in operation. Effective dissipating of this heat happens with an efficient cooling system, whether air-based or water-based, lest the laser source overheats and improves on performance and lifetime as well.

Exhaust System

Exhaust system prevents fumes and particles from the workpiece from settling during the process of engraving. This is in order to attain consistent results by ensuring that there are clean laser optics, and it also minimizes worker interaction with the hazardous contaminants, thus facilitating proper safety in a workplace.

Ventilation

In this, proper ventilation takes away fumes and smokes thereby avoiding pollution into the workplace. It is dependent on operator safety and also avoids residues on etched material.

Power Supply

Basically, power supplies are made to provide steady reliable power. The laser source together with other components demands a constant supply of power for better performance and free from power fluctuations which would thereafter have an impact on the engraving quality.

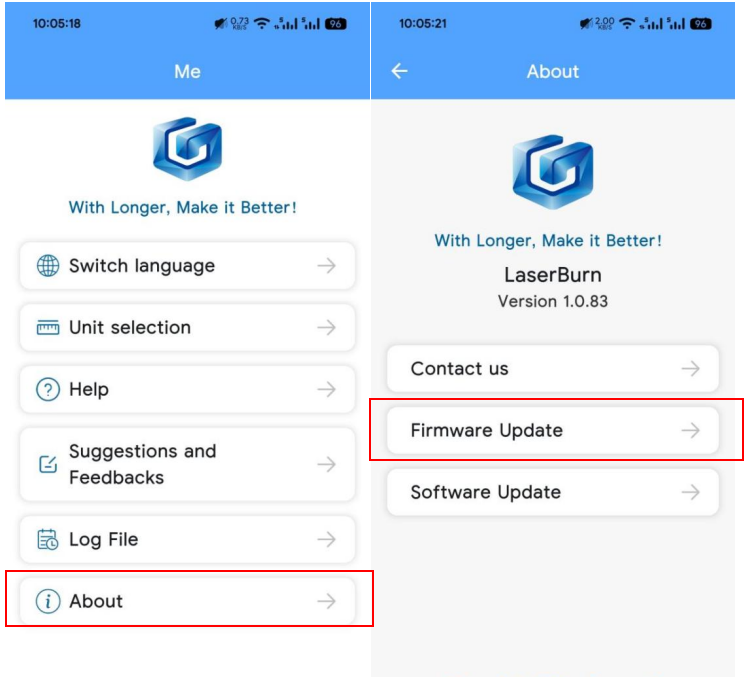

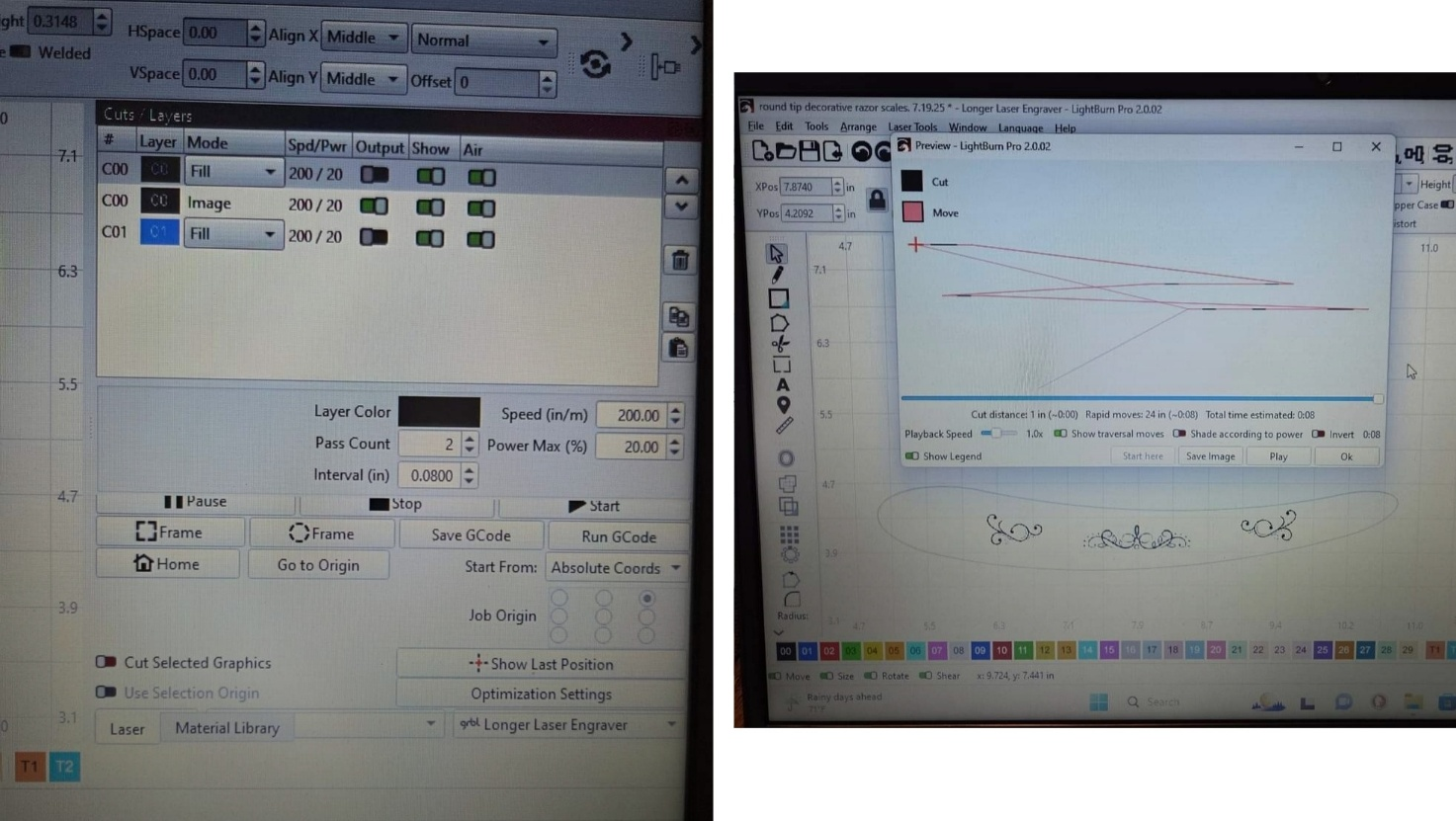

Control Software

Control Software acts as a user interface allowing operators to import, edit then optimize designs. Flexibility with common design programs along with machine manufacturer-specific software increases control and customization.

Exploring Different Power Capacities: 5W, 10W, 20W, and 40W Laser Engravers

5W Laser Engraver

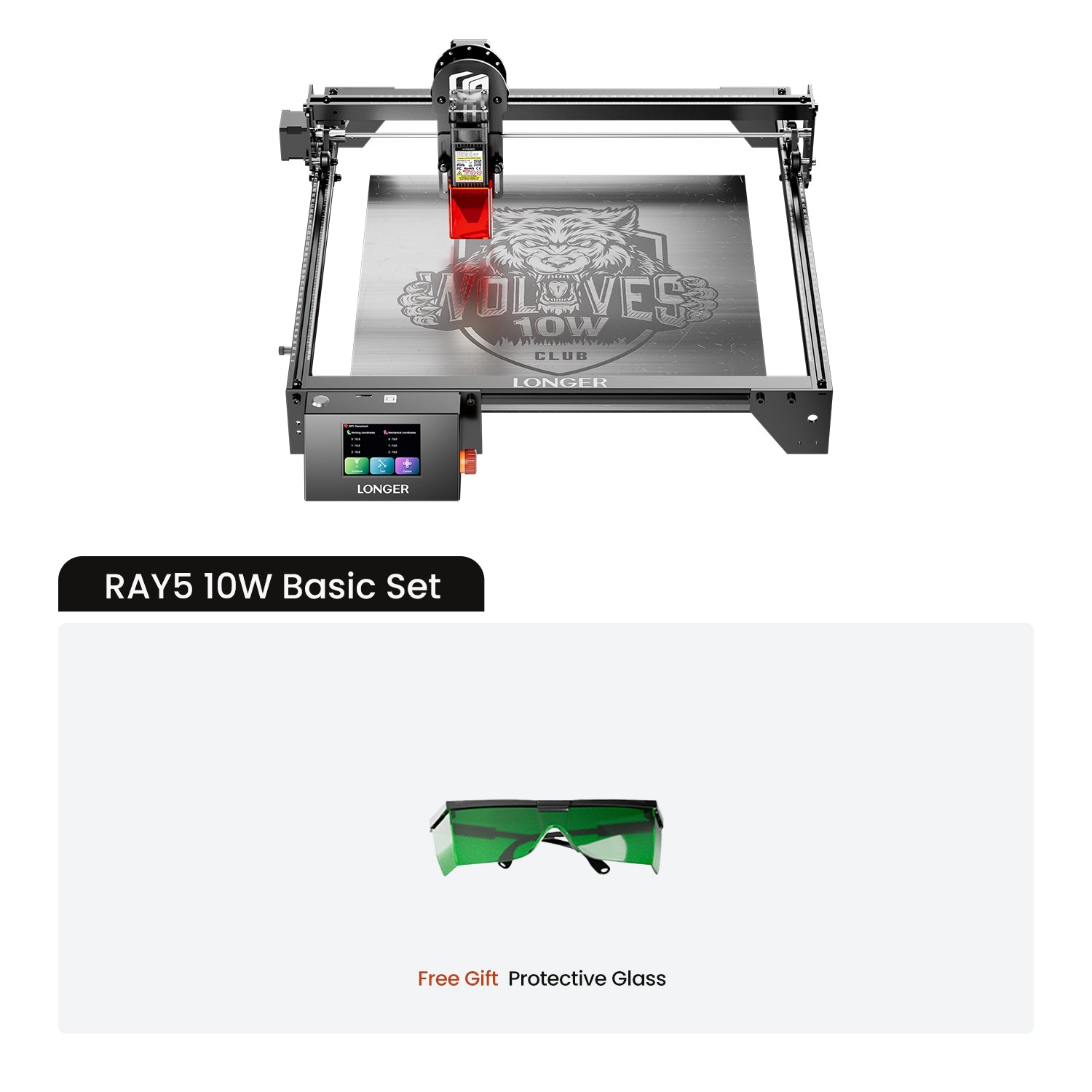

Beginners should start with a 5W laser engraver like the Longer RAY5. This entry-level laser engraving machine is perfect for beginners due of its accuracy and price. Users may confidently create using the RAY5 5W's application-focused design.

10W Laser Engraver

Upgrading to a 10W laser engraver makes sense as your abilities and projects grow. The RAY5 10W boosts power and versatility for engraving operations. This update permits finer engraving and thicker material cutting, expanding your creative possibilities.

20W Laser Engraver

A 20W laser engraver offers even more flexibility and speed. A 20W machine can deal with a range of materials, making it a popular option for companies and amateurs that value efficiency and speed.

40W Laser Cutter

A 40W laser cutter is best for demanding tasks. These powerful machines are ideal for engraving and cutting wood. A 40W laser cutter is used in bulk production and complicated crafts for accuracy and efficiency.

Applications of Laser Engraving Machines

Wood Engraving and Cutting

Laser engraving devices make woodworking more adaptable and accurate at decorating wooden surfaces. These machines create elaborate patterns, enabling artists and producers to give furniture detailed designs. Laser cutting also allows precision wood contouring, allowing intricate and bespoke wooden items. Laser engraving enhances woodworking creativity and workmanship, whether decorating furniture or making unique presents.

Metal Engraving and Marking

Beyond carpentry, laser engraving is essential in metals. Lasers mark metal surfaces precisely. Businesses that need accurate and permanent marks on metal components for identification and traceability benefit from this capability. Laser engraving on metal allows detailed patterns and branding and fulfills industrial requirements.

Personalization and Customization

Laser engraving equipment provides tremendous customization and personalization across materials. These devices let people and organizations to personalize their goods by engraving names and trademarks on personal items or producing intricate patterns on various surfaces. Laser engraving can customize promotional materials, awards, and unusual presents to meet the rising need for customized and distinctive things.

Signage and Branding

Laser engraving machines are essential for high-quality signs and branding. Lasers reproduce logos, text, and images precisely, giving firms a polished and professional look. Laser-engraved signs on acrylic, wood, metal, or other materials boosts visibility and brand identification. This technology helps create eye-catching displays, promotional materials, and durable outdoor signs, enhancing a business's branding strategy.

Laser Marking Machines

Laser engraving involves laser marking equipment, which mark different materials. These robots help companies comply with industry requirements by identifying and tracking products. Laser marking permanently and precisely labels objects with serial numbers, barcodes, and other important information. Laser marking equipment help manufacturers, electronics, and healthcare companies enhance product quality and inventory management.

Choosing the Right Laser Engraving Machine for You

Consider Your Needs

Before buying a laser engraving equipment, evaluate your needs. Consider whether you like engraving or cutting and the tools and resources you will need. Understanding your needs will help you choose a machine.

Power Requirements

Consider laser power. A 5W or 10W machine may be enough for hobbyists or engravers. Commercial and material-handling businesses may profit from a 20W or 40W equipment with higher power output.

Budget Considerations

Laser engraving machines vary in price. Start with a needs-based budget and investigate choices within it. Think about accessories and upkeep, not just the initial cost.

Brand and Model

Prioritize reliable and high-performing brands and models. RAY5 series 5W and 10W models are worth considering. This series balances quality and price.

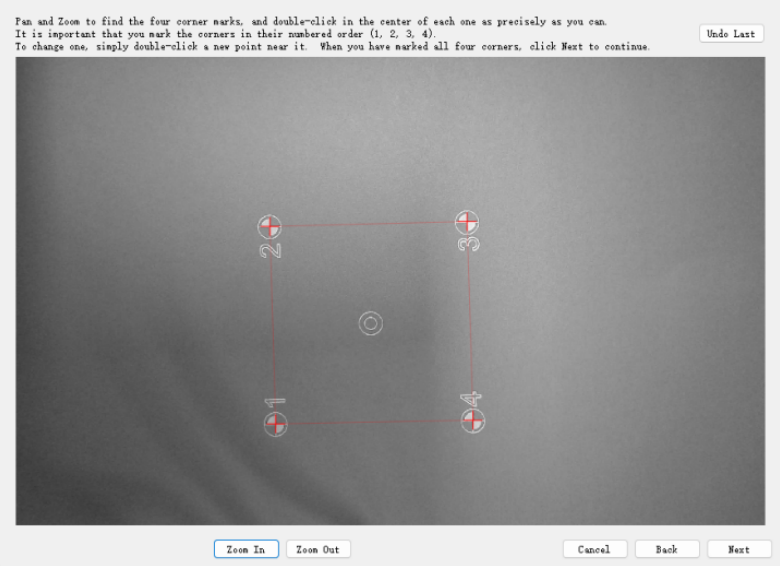

Ease of Use and Software Compatibility

Laser engraving machines should be easy to operate and compatible with design software, especially for beginners. Make the machine compatible with your design tools for convenience.

Material Compatibility

Choose a laser engraving equipment that works with your materials. Different machines can engrave or cut wood, acrylic, leather, glass, or metal. Check if the equipment can handle your project materials.

Workspace Size

Consider the machine's engraving or workspace size. Working space may increase for larger projects. Make sure your materials fit in the machine's area.

Speed and accuracy

Examine laser engraving equipment speed and accuracy. Machine speed affects productivity, particularly for commercial use. Engraving delicate details requires precision. Find the ideal balance.

The Future of Laser Engraving Technology

Laser engraving equipment evolve with technology. Future developments include artificial intelligence for precision, automation for efficiency, and eco-friendly laser technology. The crystal ball of technological progress shows various trends and innovations that foretell the future.

Integration of Artificial (AI) Intelligence

Laser engraving will benefit greatly from artificial intelligence. The accuracy and efficiency of laser engraving equipment are improving with AI algorithms. These clever technologies assess designs, optimize engraving paths, and adjust to material qualities in real time for unmatched accuracy.

Increased Automation for Efficiency

Laser engraving will require automation in the future. Automation technologies like self-calibrating equipment and automated material management will simplify engraving and reduce human participation. This boosts productivity and frees up operators' time for harder tasks, balancing machine accuracy and human innovation.

Environmental Considerations

As industries prioritize sustainability, laser engraving technology should follow suit. Future machines may use greener laser sources and energy-efficient parts. Manufacturers may reduce waste and optimize energy use to follow the worldwide eco-conscious trend.

Multi-Material Capabilities

Laser engraving equipment will likely handle more materials in the future. Current machines are good at engraving wood, metal, and plastics, but future models may engrave ceramics, glass, and composites. This adaptability expands inventiveness and applications.

Miniaturization and Portability

Technological advances reduce design size. Future laser engraving equipment may shrink to make them more portable. This could make laser engraving technology more accessible to individuals and small businesses, removing the need for large, specialized spaces.

Enhanced Connectivity and Remote Operation

IoT technology could increase laser engraving equipment connectivity and remote control. Workers might remotely monitor and handle equipment for a more flexible and responsive workflow. Laser engraving may also use cloud-based design-sharing and collaboration systems.

Holographic and 3D Engraving

More advanced holographic and 3D engraving methods may replace 2D engraving. This could enable rich, three-dimensional designs with texture and depth. Such advances would be used in industrial prototypes, jewelry, and art.

Conclusion

The exciting realm of laser engraving machines combines creativity and accuracy. From 5W engravers to 40W laser cutters, these technologies have transformed industrial branding, carpentry, and customization. As laser engraving equipment technology evolves, companies and inventors have more options. Whether you're a company seeking cost-effective production solutions or a hobbyist learning engraving, laser engraving equipment can unleash your creativity.