My journey into the world of laser engraving began about three years ago, when I started my first job at an institution managed by the local government. It was a special workplace that hired only disabled people like me. At first, I was simply helping a colleague handle sheets of plywood — his hands were too weak to position them correctly under the laser cutter.

1. A Humble Beginning

That machine was huge, an 80W CO₂ laser engraver, and I was fascinated by its precision and power. Over time, I learned more and more about how it worked. After a few months, I became the main operator in the company, managing the laser engraver on my own. It was an amazing feeling — I could finally show what I had learned and see tangible results every day.

Working under time pressure didn’t scare me. In fact, I loved it. We produced all kinds of products from plywood, such as phone drawers, boxes, and custom signs. Each project taught me something new, and I knew this wasn’t just a job — it was the start of something bigger.

2. A Leap Toward Independence

After two and a half years in that company, I felt it was time to change something in my life. I wanted freedom — to make my own decisions, manage my own time, and build something from scratch. The biggest motivator, of course, was also financial independence.

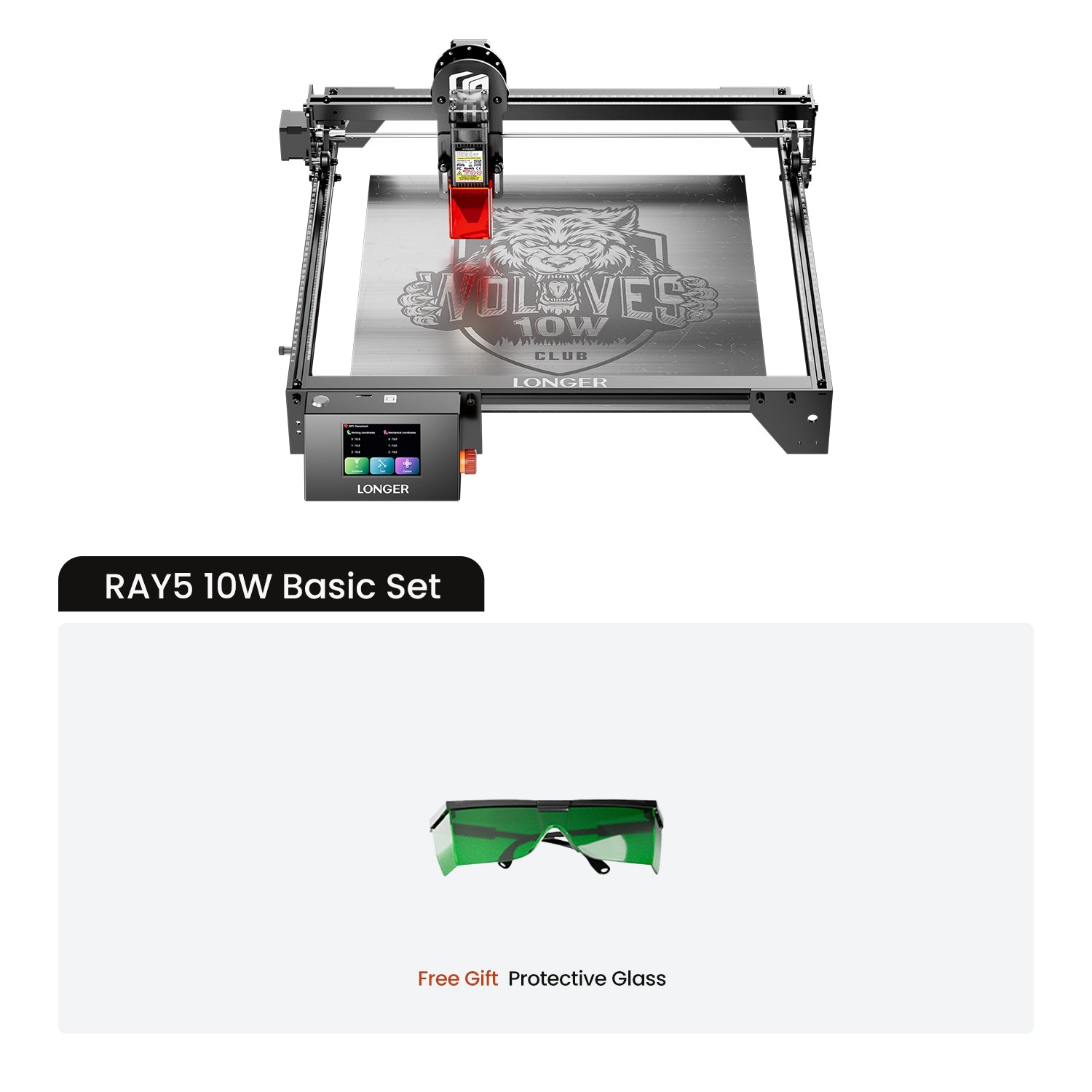

That’s when I decided to start my own small business. I invested my savings in my very first laser engraver — the LONGER Ray5 10W.

The day it arrived, I was full of excitement and nervousness. Setting it up, learning the software, experimenting with materials — everything felt new again. But soon after, my first few orders came in: engraved pictures, small decorative boxes, and a few custom gifts made from 3mm plywood.

When I earned my first money from those orders, I felt an incredible sense of pride. It wasn’t just about the income — it was proof that I could do this on my own. That moment gave me the motivation to keep improving, learning, and growing my business.

3. The Christmas Rush — and a New Challenge

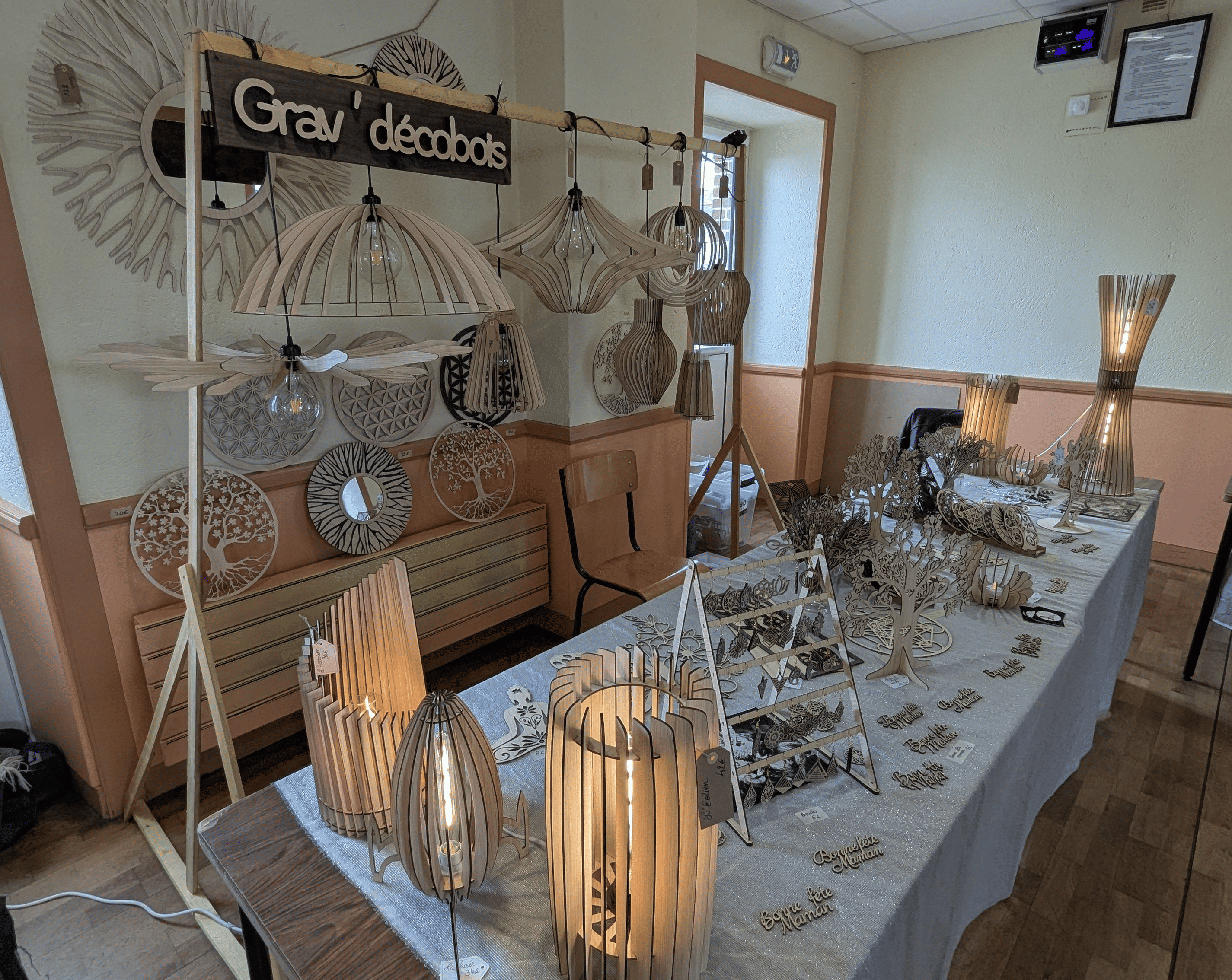

By October 2024, I started preparing for the Christmas season — one of the busiest times for any maker. I designed new products such as wooden baubles, lanterns, and ornaments, all made from 3mm plywood. In early November, I received a few small orders for lanterns, and I used my 10W machine to produce them.

However, within just a week, the number of orders exploded. Suddenly, I was working 12–14 hours a day trying to keep up, and I realized that my 10W engraver alone wouldn’t be enough to meet the demand.

That’s when I made one of the best decisions in my business journey — I bought a LONGER Ray5 20W.

The difference was immediately noticeable. The stronger laser cut faster and more precisely, allowing me to handle twice the workload. My lanterns became my top-selling product, and by using both my 10W and 20W engravers together, I was able to complete all orders on time before Christmas.

When the last order shipped out, I finally had time to breathe — and count my earnings. The total profit for the season was about $500, a milestone that made all those sleepless nights worth it.

4. Reinventing and Upgrading

After the New Year, I decided to reinvest my earnings. I purchased an air assist system for my 20W Ray5, and it completely changed the game.

The cutting quality improved dramatically — cleaner edges, no burn marks, and much smoother results. Even better, the cutting time was nearly twice as fast. I realized that small upgrades can make a big difference in productivity and product quality.

5. Expanding Sales Channels

As my confidence grew, so did my customer base. Most of my sales came through my Facebook fan page and various maker groups. I also received direct messages from people who knew me personally and wanted custom pieces.

But I wanted to reach a larger audience, so I started planning to list my products on Allegro, one of the biggest online marketplaces in Poland. I believe this will help me expand faster, reach new customers, and generate more consistent income.

For now, I sell both offline and online, and every sale — no matter how small — reminds me why I started this journey in the first place.

6. Preparing for My First Exhibition

This year marks another exciting step — my first maker exhibition. I’m preparing new and unique items: bamboo pens, plywood eggs, and even engraved slate tiles.

Recently, I’ve been experimenting with glass engraving — it’s not perfect yet, but I’m learning and improving. My next goal is to master engraving on metal bottles and thermal mugs, as I believe expanding the range of materials will open new markets and opportunities.

Every experiment, even the failed ones, brings me closer to mastering the art of laser engraving.

7. Lessons Learned and Advice for Beginners

If I could give one piece of advice to anyone starting their journey in this amazing world of laser engraving, it would be this: Never give up.

When I started, I made countless mistakes — I burned through piles of plywood sheets because I used too much power or moved too slowly. But every mistake was a lesson.

One of the most useful tools I discovered is the Material Test feature in LightBurn software. It allows you to test different power and speed settings to find the perfect parameters for your material. You can also find ready-made material settings for free on the LONGER website, which is extremely helpful for beginners.

For me, engraving is no longer just a job — it’s a lifestyle. It’s about creativity, precision, and freedom. Watching an idea come to life through a beam of light still amazes me every single day.

8. Looking Ahead

Today, I continue to grow my small business with big dreams. My goal is to turn my workshop into a professional engraving studio, expanding both my skills and my product line.

From my first 10W engraver to managing multiple machines and preparing for exhibitions, every step has been a challenge — but also a reward.

If my story proves anything, it’s that with passion, persistence, and the right tools, anyone can turn their hobby into a thriving business.

And for me, that journey started with the LONGER Ray5 laser engraver.