Products

Trending searches

Popular products

Cart ($0)

Cart ($0)

Longer Nano & Longer Nano Pro are two very practical and versatile Laser Engravers, capable of creating various creations quickly thanks to the Galvo-Laser system they are equipped with. In order to ensure accuracy and precision, each individual unit is manually calibrated through multiple factory jig tests, which ensure maximum engraving performance; for this reason, it is normal that the metal base is not perfectly aligned with the pattern of the laser module, as the base is mass-produced while the Laser-Head is calibrated manually. However, you can easily get a grid that is perfectly aligned with the Laser-Head, so you can use it to align the objects to be engraved.

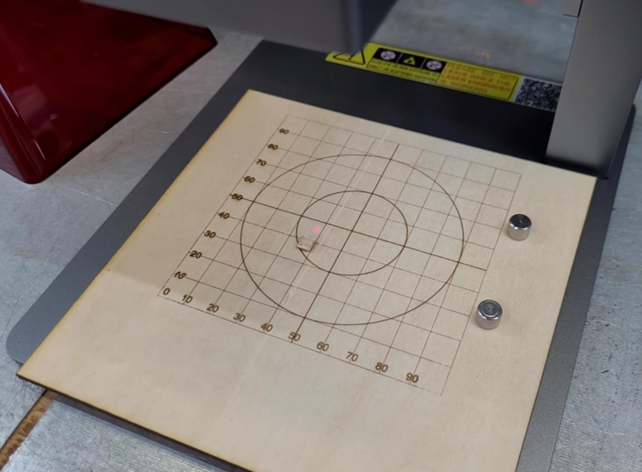

After doing this, in Lightburn we draw a grid based on 10x10 centimeters or 100x100 millimeters (depending on your preference), then proceed to engrave it on the piece of plywood.

The newly engraved grid is perfectly aligned with the Laser-Head, so you can use this grid as a reference for engraving. For example, by placing a business card on the grid, as shown in the figure, it will be very easy to make a precise engraving as it will be sufficient to use the same coordinates of the grid even within the virtual grid of Lightburn.

This is a simple and functional method to get a reference grid on the Longer Nano & Longer Nano Pro, however you have to be careful never to move the plywood panel. In fact, if it is moved even a little, the reference will be lost, and it will be necessary to repeat the whole process with a new plywood panel and a new engraved grid.

In conclusion, a grid engraved directly with your laser provides an invaluable visual reference for positioning objects, ensuring perfect alignment with the laser beam. Provided that the grid remains immobile, this solution allows for flawless synchronization between the Lightburn visualization interface and the actual position of the workpiece to be engraved; This not only improves the accuracy and repeatability of machining, but also significantly reduces material waste due to incorrect positioning. In addition, having a fixed and precise reference point directly on the work area makes it easy to set up complex jobs that require multiple or multi-face engravings of the same object, acting as a constant and reliable guide for the user.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!