Products

Trending searches

Popular products

Cart ($0)

Cart ($0)

ABSTRACT

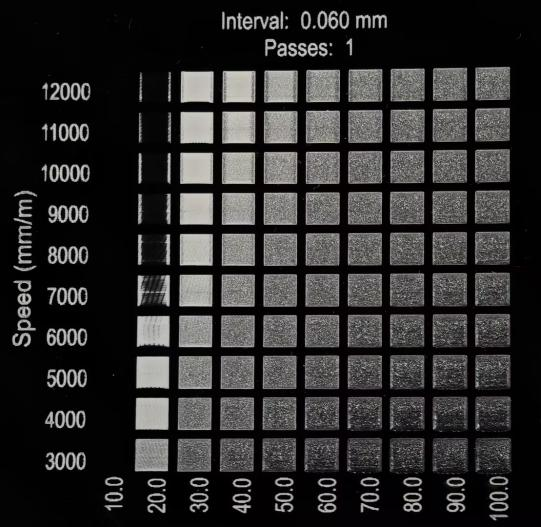

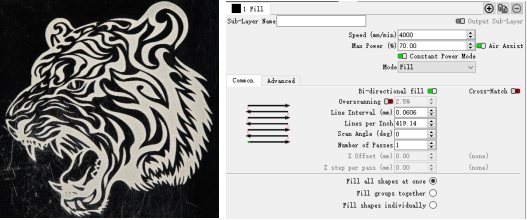

This paper takes Nano Pro model laser engraving machine as an example to systematically explore the image engraving process on black acrylic (casting process plate). First, the performance difference between cast and extruded acrylic is compared, and it is determined that cast plate has better adaptability to complex shapes; then in LightBurn software, the speed is set to 10000 mm/min and the power is set to 30%, and the graphics to be engraved are imported and measured to evaluate the engraving effect of this parameter combination.

Acrylic is a high-performance plastic material that can be used for DIY engraving crafts, etc. This paper takes Nano Pro model as an example to test the engraving effect of black acrylic with different processes:

1. Material selection

According to different production processes, acrylic can be commonly divided into two types: casting process and extrusion process.

The casting process is to heat the acrylic particles to a molten state and pour them into the mold for cooling and solidification. The characteristic of this production process is that it can produce larger and more complex shapes, but the surface smoothness is slightly worse.

The extrusion process is to heat the acrylic particles to a molten state and then extrude them into shape through an extruder. This production process is characterized by high production efficiency, good product uniformity, high surface smoothness, and the ability to produce larger-sized plates.

This article takes cast acrylic as an example to perform an engraving parameter matrix, as shown in the figure below:

Casting type

Conclusion

Nano Pro can obtain clear grayscale levels and sharp edge details on a black cast acrylic plate at a speed of 10000 mm/min and a power of 30%. Acrylics with different production processes have their own advantages in surface smoothness and detail restoration. It is recommended to select the appropriate plate type according to project requirements, and on this basis, fine-tune the speed and power parameters to achieve the best engraving quality.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!