Products

Trending searches

Popular products

Cart ($0)

Cart ($0)

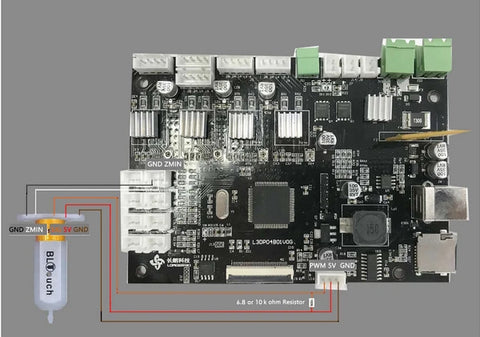

This article is to help the LONGER LK and LK Pro series 3D printer users who want to upgrade with auto bed leveling sensor, like BL-TOUCH, etc. More information about senor please refer to the sensor datasheet.

LKx series board wiring need extra resistor

LKx Pro series board wiring

Remove the z min end stop switch

2. Screw down the left 2 screws of head module

3. Mount BL-TOUCH as picture showing below

Mount sensor

-- BL-TOUCH START GCODE --

G21 ; metric values

G90 ; absolute positioning

M82 ; set extruder to absolute mode

M107 ; start with the fan off

; confirm BL-touch safety

M280 P0 S160 ; BL-Touch Alarm release

G4 P100 ; Delay for BL-Touch homing

G28 X0 Y0 ; move X/Y to min endstops

G28 Z0 ; move Z to min endstops

; reconfirm BL-touch safety

M280 P0 S160 ; BL-Touch Alarm realease

G4 P100 ; Delay for BL-Touch

; bed leveling

G29; Auto leveling

M420 Z5 ; set LEVELING_FADE_HEIGHT

M500 ; save data of G29 and M420

M420 S1 ; enable bed leveling

; prepare hot-end

G92 E0 ; Reset Extruder

G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed

G1 X0.1 Y20 Z0.3 F5000.0 ; Move to start position

G1 X0.1 Y150.0 Z0.3 F1500.0 E15 ; Draw the first line

G1 X0.4 Y150.0 Z0.3 F5000.0 ; Move to side a little

G1 X0.4 Y20 Z0.3 F1500.0 E30 ; Draw the second line

G92 E0 ; Reset Extruder

G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed

G1 X5 Y20 Z0.3 F5000.0 ; Move over to prevent blob squish

; -- end of BL-TOUCH START GCODE --

PC Software: >>pronterface-windows<<

Mounted Bracket: >>Bracket<<

The firmware has been codeed by LONGER, you would download the firmware and upgrade directly:

>>For LK1(U20)<<

>>For LK4(U30)<<

>>For LK5 PRO<<

If you have installed dual blower kit, use the dual blower kit Mounted Bracket: >>Bracket<<, and download the below firmware and upgrade directly:

>>For LK1(U20)<<

>>For LK1 Plus(U20 Plus)<<

>>For LK4(U30)<<

>>For LK4 PRO(U30 Pro)<<

>>For LK5 PRO<<

If there's any question or need for assistance from us on the upgrade, please feel free to contact us at support@longer3d.com, LONGER support team will follow up and reply you ASAP.

Thanks.

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!