Products

Trending searches

Carrello ($0)

Carrello ($0)

INTRODUCTION

Red and blue lasers are two prevalent choices in the engraving machine market, each equipped with distinct laser heads. These laser heads offer unique performance characteristics and applications. By comprehending the disparities between red and blue lasers, we can make informed decisions to enhance production efficiency and quality. This article delves into the variances between red and blue laser engraving machines, using the LONGER RAY5 20W laser engraving machine and the LONGER Ruby Pulsed Infrared Laser Module as a case study.

Features of red laser engraving machine

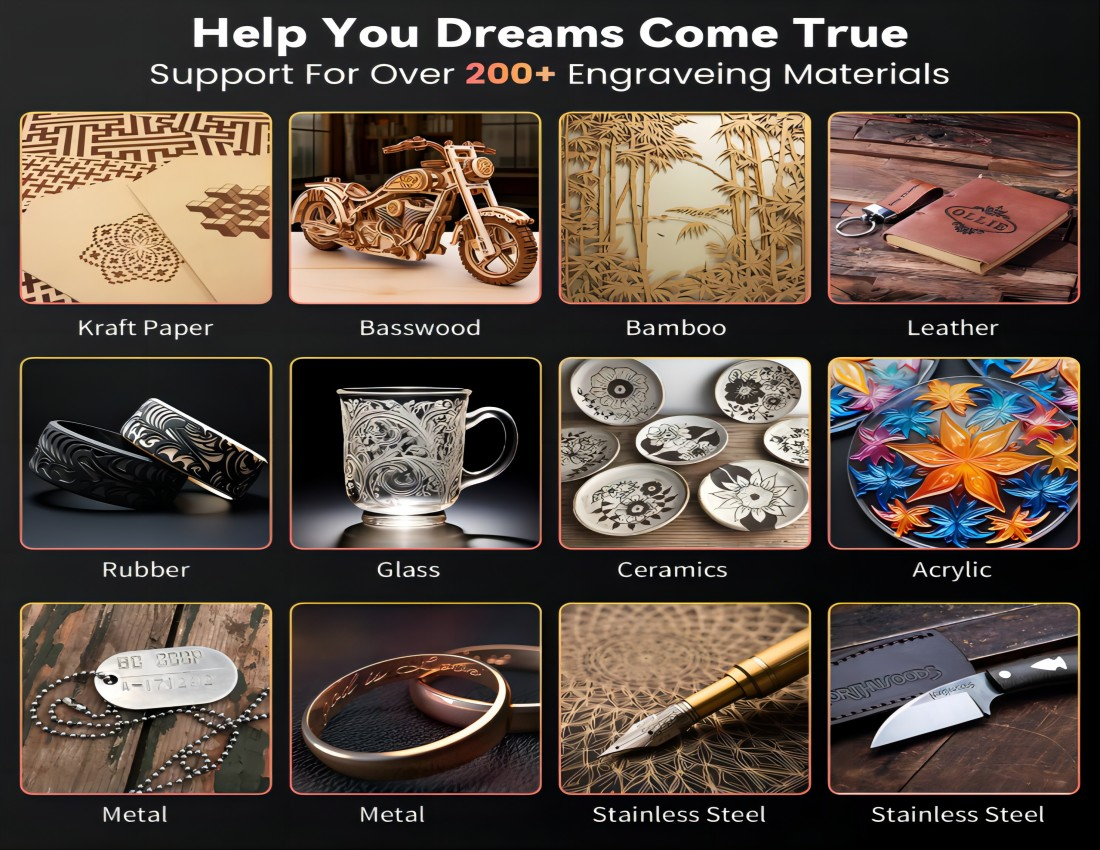

Red light laser engraving machines usually use longer wavelength red light as the engraving light source, which has higher penetrating power and larger spot diameter. This makes it excellent at handling thicker materials such as wood, leather, and certain non-metallic materials. In addition, red light laser engraving machines also have high engraving speed and low cost, so they are popular in mass production and rapid prototyping.

Application of red laser engraving machine

LONGER Ruby PulsedInfrared Laser Module is a red laser head developed by the LONGER team. It uses advanced technology and an ultra-fine laser spot size of 0.03*0.03mm, which can easily achieve complex details down to millimeters, and can be produced on metals, plastics, etc. Perfect carving. LONGER Ruby has unparalleled engraving capabilities from metals and alloys such as iron, copper, aluminum, magnesium, zinc, gold, silver and titanium to other materials such as metal oxides, plated surfaces, ABS, inks and epoxies. When the laser engraving comes to engraving on glass, the choice of LONGER Ruby Pulsed Infrared Laser Module ensures seamless engraving without any tinting, showcasing its remarkable efficiency and speed in completing tasks while maintaining the clarity and precision of the design. Particularly suitable for scenarios requiring processing of thick materials and large-scale production, for instance, in industries like engineering and leather product manufacturing, Ruby Pulsed Infrared Laser Module offer unmatched efficiency in completing engraving tasks, thereby significantly enhancing overall production efficiency.

Features of blue laser engraving machine

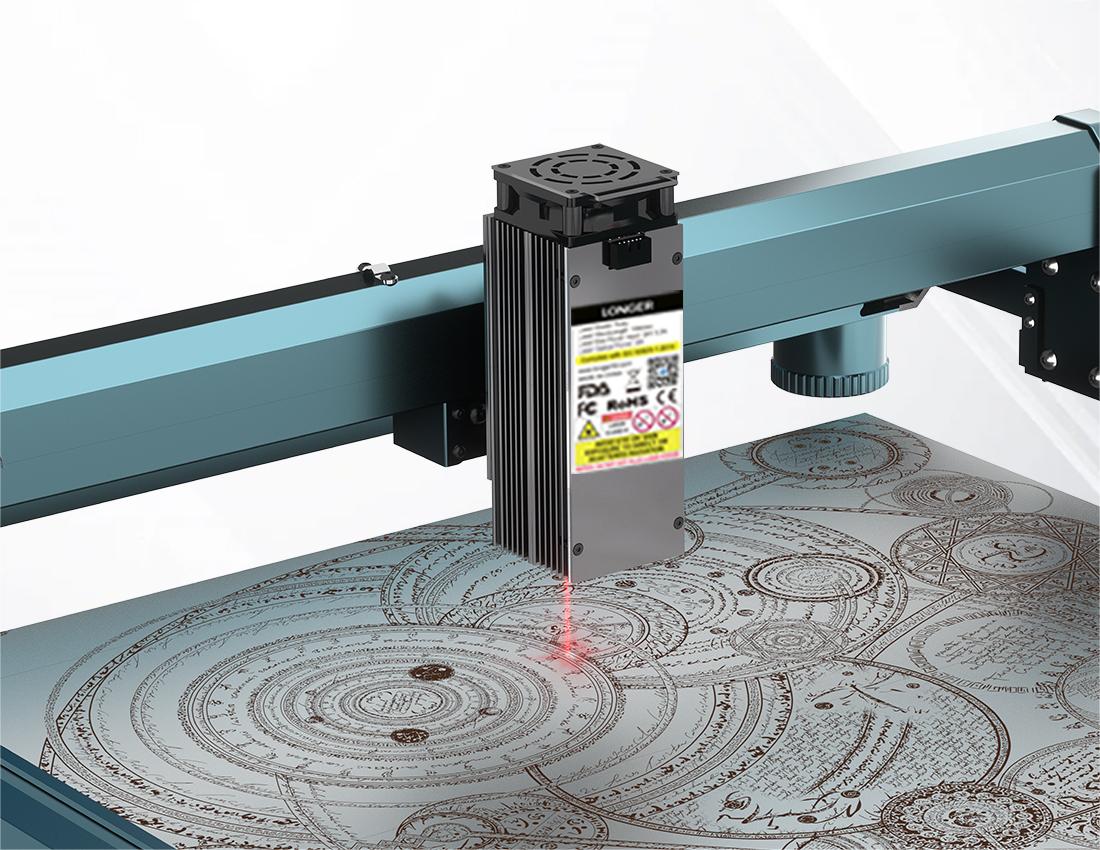

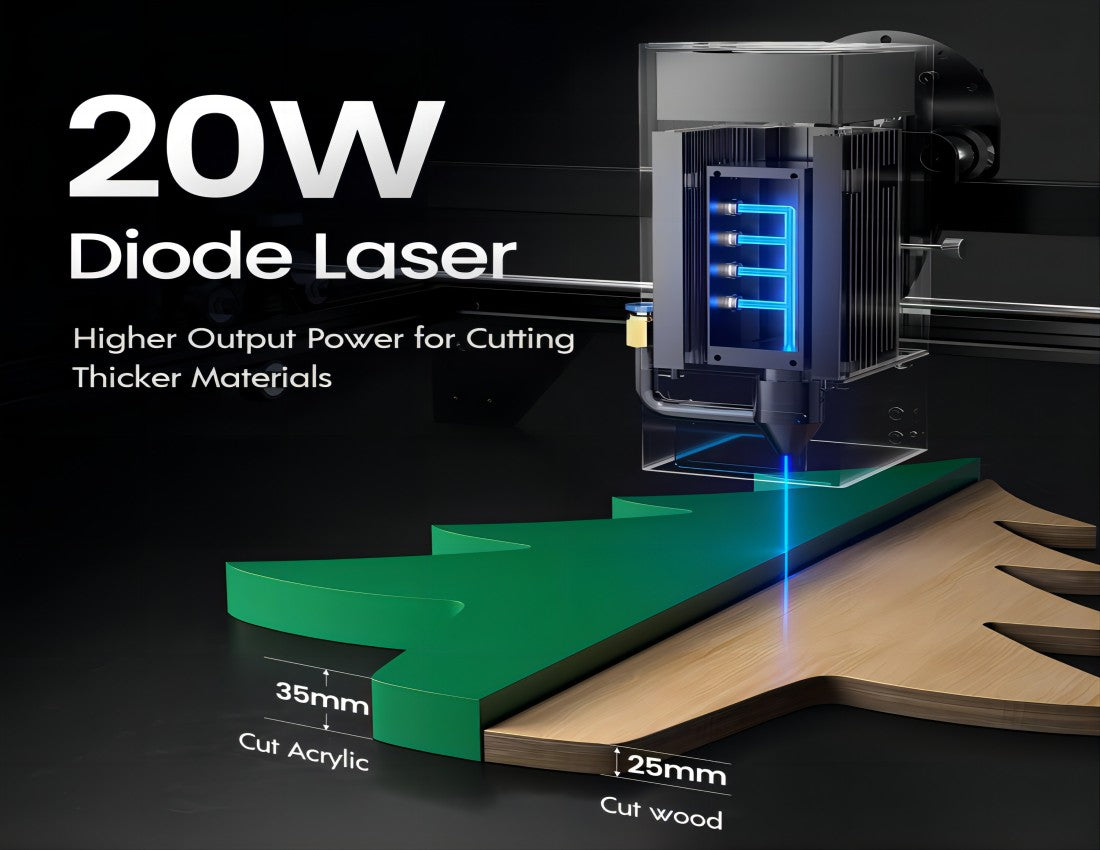

Blue light laser engraving machines use shorter wavelength blue light as the engraving light source, with higher resolution and smaller spot diameter. This makes it excellent at handling thin materials such as paper, plastic and metal films. Blue light laser engraving machines also have high engraving accuracy and low heat output, so they have advantages in fine engraving and high-precision cutting.Longer's LaserB1 series and Ray5 laser engraving machines represent prime examples of blue laser engraving technology, maintaining their blue laser functionality without the need for a laser head change.

Application of blue laser engraving machine

LONGER RAY5 20W blue light laser engraving machine is a four-core diode laser with 22-24W output power and strong cutting ability. Its ultra-fine 0.08*0.1mm focus and 10000mm/min burning speed can effectively engrave on metal surfaces. Achieve multi-color engraving, and support multiple connection options, such as WIFI, APP, USB and TF card. For scenes that require fine engraving and high-precision cutting, blue-ray laser engraving machines have more advantages. They can easily achieve detailed engraving while avoiding material deformation due to high temperatures. For example, in the electronics industry, precision instrument manufacturing and other fields, blue-ray laser engraving machines can achieve high-precision engraving and cutting to meet product accuracy requirements. In addition, blue light laser engraving machines are also widely used in art production, anti-counterfeiting markings and other fields.

Conclusion

Red light and blue light laser engraving machines each have their own unique advantages and application scenarios. When choosing a laser engraving machine, creators should choose the appropriate model according to specific needs. Understanding the differences between red light and blue light is of great significance for us to choose the appropriate and accessories equipment. With 8 years of professional research in laser engraving machines, LONGER is committed to advancing the research, development, and application of laser engraving technology, delivering technological innovation and economic benefits to various industries. In the future field of laser engraving, the power of precision will continue to lead us to broader application prospects.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!