CONTENTS

Trending searches

Wagen ($0)

Wagen ($0)

ABSTRACT

In laser cutting and engraving, path optimization is a core technique for achieving efficient and precise processing. By fine-tuning the motion path of the laser head, path optimization significantly reduces idle travel time and unnecessary movements, boosting production efficiency and minimizing wear on the equipment. As a popular laser control software, LightBurn offers powerful path optimization tools to help users manage complex cutting jobs with maximum performance.

This article explores how path optimization works in LightBurn, common strategies used, and how to configure the related settings.

1. What Is Path Optimization?

Path optimization refers to the strategic arrangement and adjustment of cutting paths to maximize efficiency and reduce unnecessary movement of the laser head. Specifically, it includes:

a) Shortest Path Selection:

Choosing the shortest possible path for the laser to minimize idle movements.

b) Path Sorting and Merging:

Ordering multiple paths logically to avoid backtracking and redundant movements.

c) Cut Order Optimization:

Organizing the cutting sequence to prevent repeated travel over the same area.

d) Travel Optimization:

Reducing non-cutting (traveling) moves and minimizing rapid jumps between points.

The goal of path optimization is not only to save time, but also to reduce material waste and extend machine life. A well-optimized cutting path is key to increasing productivity and processing quality.

2. Main Optimization Strategies in LightBurn

LightBurn provides several built-in path optimization strategies to support efficient operation even in complex designs. Below are the primary optimization directions offered

a) Optimize by Group

Group-based optimization ensures that the laser head performs continuous cutting within a group of related or similar objects before moving to another group.

How to Use: Group objects or merge layers in your design. LightBurn will prioritize cutting paths within each group.

Benefits: Reduces unnecessary travel and backtracking, improving overall cutting speed and workflow efficiency.

b) Optimize by Layer

Layer-based optimization organizes cutting tasks according to layer priority, ensuring each layer is completed in an optimal sequence.

How to Use: Assign specific cut orders to layers in your project. LightBurn follows this preset order to optimize the laser path.

Benefits: Prevents excessive jumping between layers, reducing idle time and enhancing productivity.

c) Optimize by Priority

Priority-based optimization allows users to define which parts of the design should be cut first, based on importance or complexity.

How to Use: Assign priority levels to different objects or paths. LightBurn will automatically follow the priority levels, cutting high-priority paths first.

Benefits: Useful for delicate or detailed areas that need to be engraved or cut first to ensure quality and avoid shifting or material issues later in the process.

3. How to Set Path Optimization in LightBurn

To enable and configure path optimization in LightBurn, follow these steps:

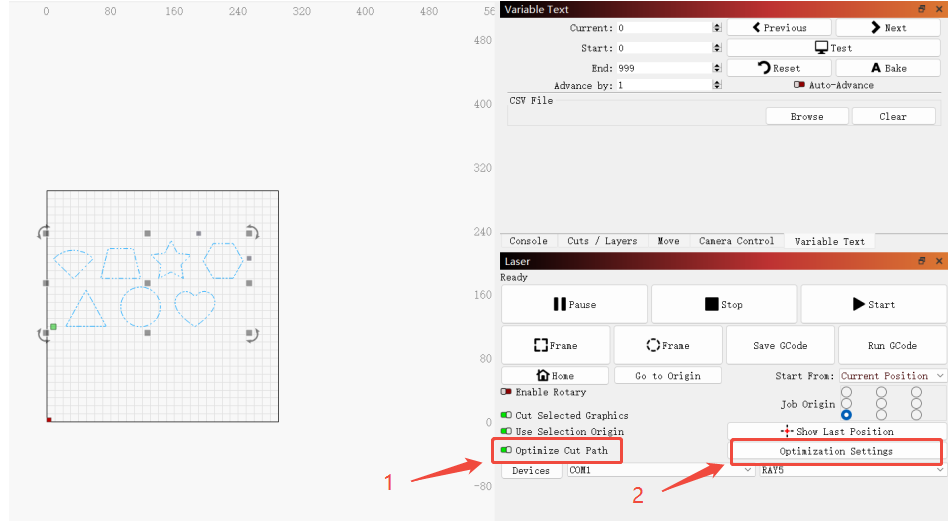

Launch LightBurn and import the design you want to cut.

On the main interface, go to the lower-right corner and enable the checkbox labeled “Optimize Cut Path.”

To customize optimization directions, click “Optimization Settings” to open the Cut Optimization Settings panel.

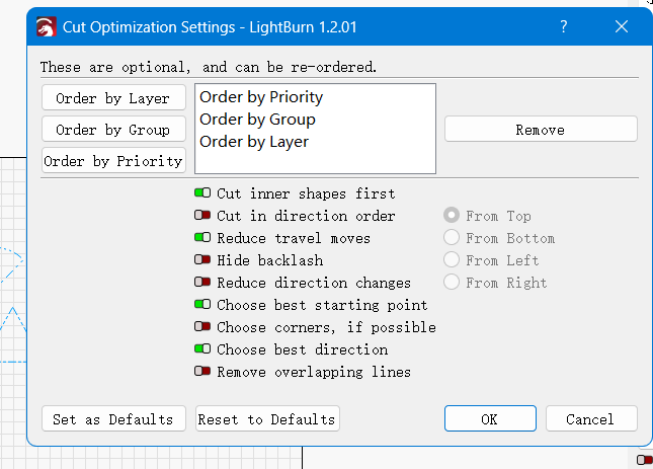

In this panel, you can configure options such as:

Order by Group

Order by Layer

Order by Priority

Additional options like inner shapes before outer shapes, reduce direction changes, etc.

With these settings properly configured, LightBurn will calculate the most efficient path for your cutting or engraving job, ensuring reduced machine time and smoother operation.

Conclusion

Effective path optimization in LightBurn is essential for improving cutting speed, reducing unnecessary motion, and extending the lifespan of your laser equipment. By leveraging features such as group-based, layer-based, and priority-based optimizations, users can streamline complex cutting jobs and achieve precise, high-quality results. Proper configuration of the Cut Optimization Settings ensures that each project is executed with maximum efficiency. Whether you're a beginner or an experienced user, mastering these optimization tools is key to unlocking the full potential of your laser system.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!