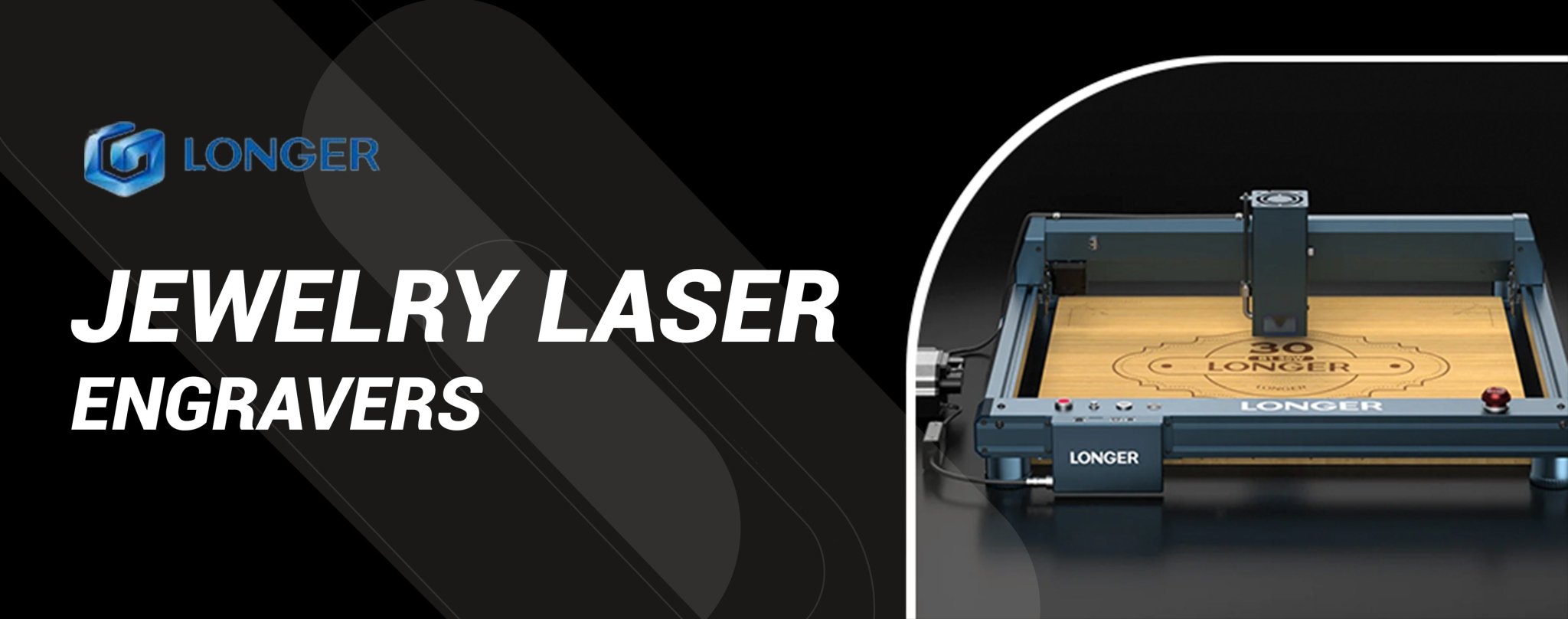

In jewelry making, customization will remain trendy in making the accessories unique and impressive. Whether you want to create meaningful inscriptions or bespoke designs, jewelry customization offers you an opportunity to express your distinctive sentiments or style. At the core of the personalization evolution is innovation and creativity and that's our specialty. At Longer, we use the exemplary power of laser technology to develop impressive tools for making unique jewelry. Our jewelry laser engravers can help you release your creative juices, giving you the ability to turn ordinary accessories into extraordinary treasures.

The Magic of Laser Engraving

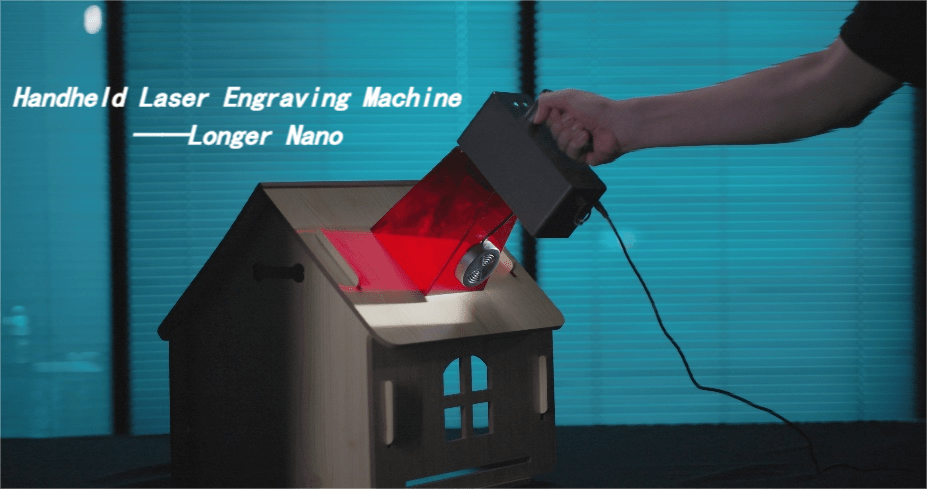

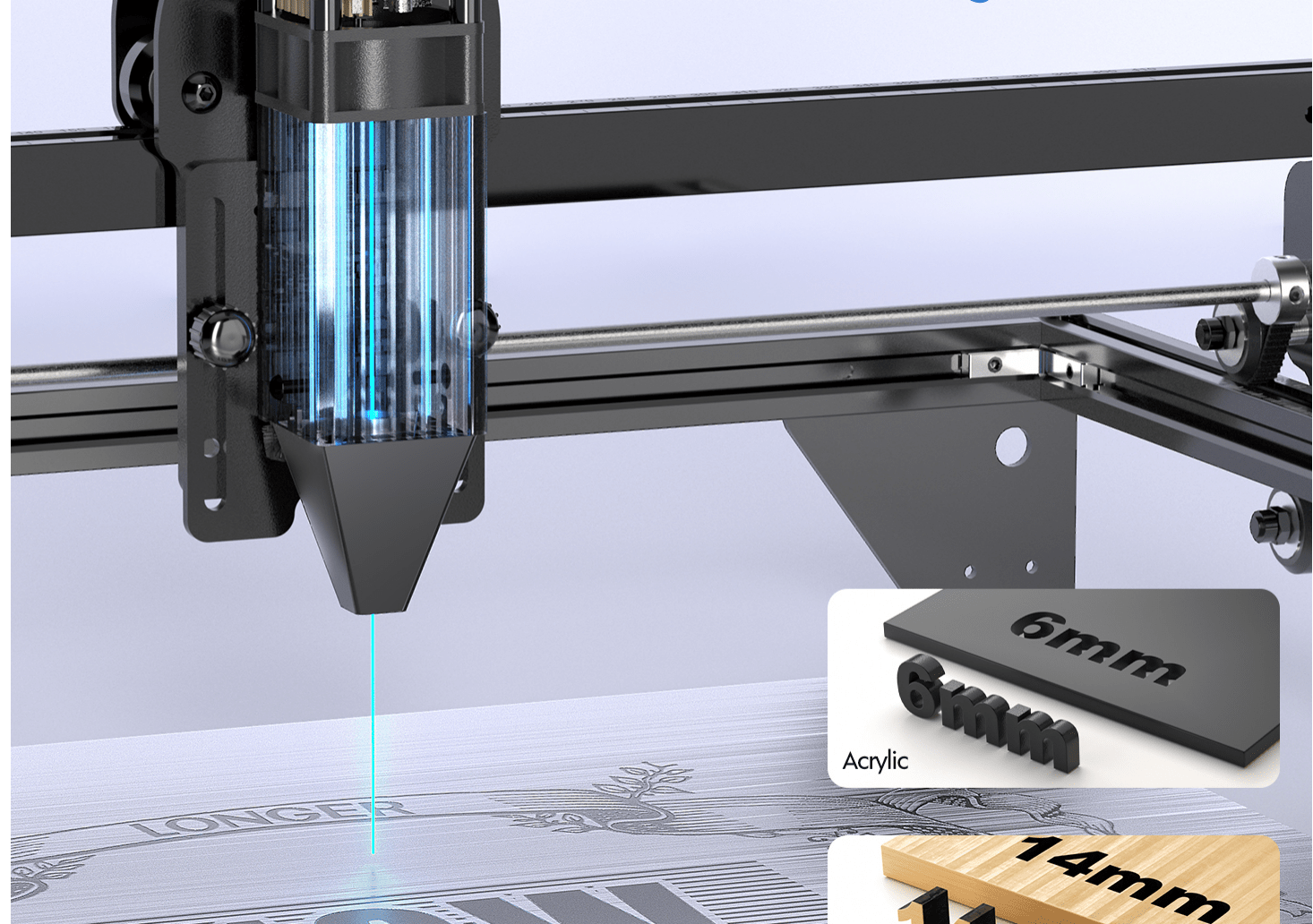

Laser engraving is a marvelous technology that has improved the efficiency of modern engineering. It uses a highly powered laser beam to inscribe designs on diverse materials accurately. The flexibility it offers is also incomparable to the conventional engraving methods. Forget the restrictions of manual engraving! This laser tackles even the most intricate designs with unmatched precision. Hard or delicate, the material doesn't matter.

Engraving Just Got Awesome! This laser engraver isn't your grandpa's tool! It tackles intricate designs with crazy precision on all sorts of materials. Think sparkling gemstones, smooth glass - no sweat! Forget limits, this engraver lets you create show-stopping masterpieces. The machine's enhanced precision has completely changed the jewelry industry, unveiling new opportunities for creativity and personalization.

Why Choose Our Jewelry Laser Engravers

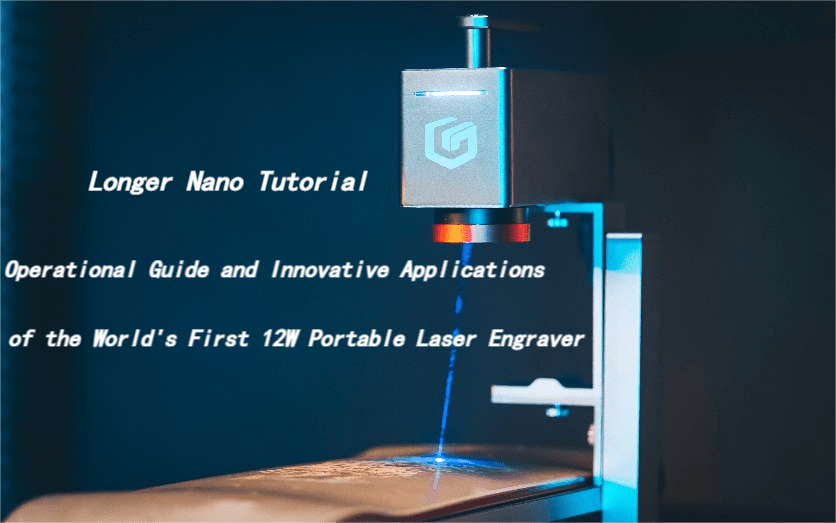

When examining the reliability and effectiveness of jewelry engraving machines, you will discover the Longer is the best option due to the following reasons. Our engravers have outstanding features such as accessibility to pros and beginners, user friendly interface, enhanced precision, and dependability in producing top-tier engraving endlessly.

When you compare our machines to the conventional ways of engraving, you will discover they have various advantages such as improved speed, unmatched precision, ability to engrave a broad range of materials. Furthermore, laser engraving has a non-contact nature that minimizes the risk of damage of very delicate pieces, giving you peace of mind while working.

Crafting Unique Jewelry Pieces

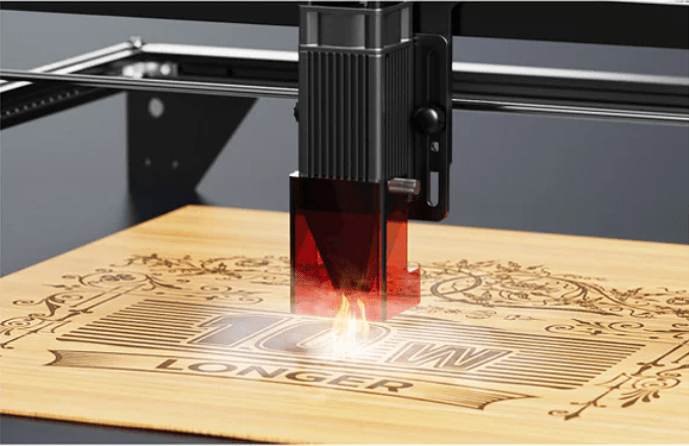

With our cutting edge laser engravers, you can uncover new possibilities in jewelry making, which you never thought existed. It doesn't matter if you are carving complex patterns on a pendant or customizing a gemstone ring, our machines can enable you to do these tasks cheaply. The flexibility of our machines will allow you to engrave with diverse materials from semi-precious stones to valuable metals.

The Longer engravers are popularly used for creating tailored rings. This machine enables crafts men to etch heartwarming messages, dates, or names, giving the ring a personal touch and enhancing its worth.

Another benefit that our machine offers is the aptitude of creating very complicated patterns and designs. With its help, you won't stress while crafting detailed motifs on your earrings, bracelets, and pendants, making simple jewelry extraordinary. These engravers also make it easier for users to etch anything on very delicate material without fear and risk of damaging it.

Tips and Tricks for Perfect Engraving

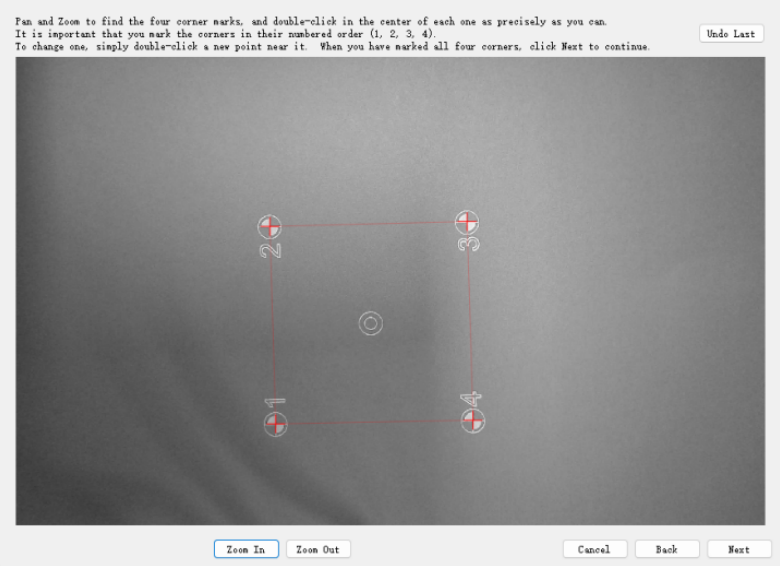

If you desire optimum results while using our jewellery engraving machine, it is vital to follow practical tips shared by the pros. First, make sure your engraving material is properly fixed in place to curb unnecessary movement while you're engraving it to maintain the design's accuracy.

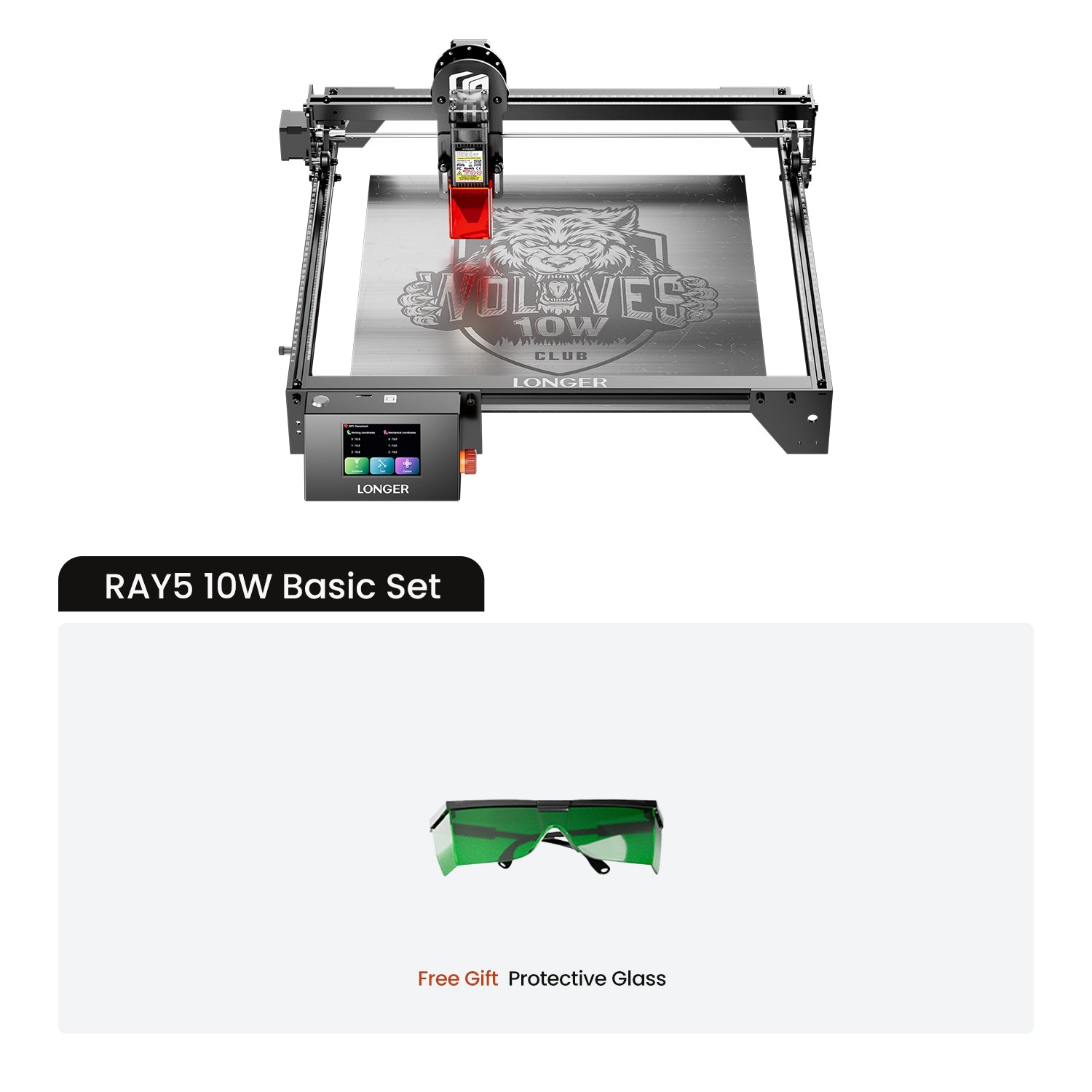

When commencing the engraving with the jewelry laser engraver, start the process with low power settings and if necessary increase it gradually. This will hinder the damaging and burning of the material. Furthermore, don't forget to put on the protective eyewear when using the laser engraver.

The mistakes many users make when using this machine is overloading it with design complexities and too much information. No need to jump into the deep end with super complex designs! Start with simpler ones and gradually explore your laser engraver's capabilities. Before you know it, you'll be a master engraver creating stunning, intricate pieces!

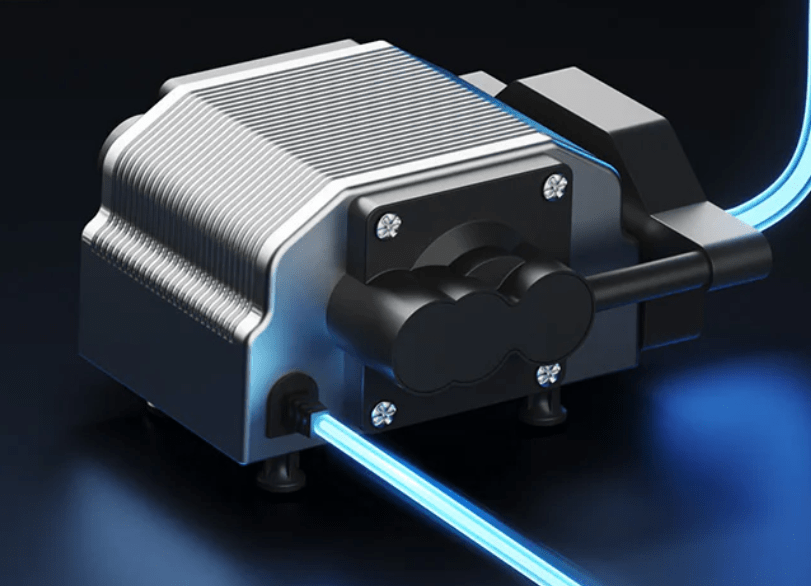

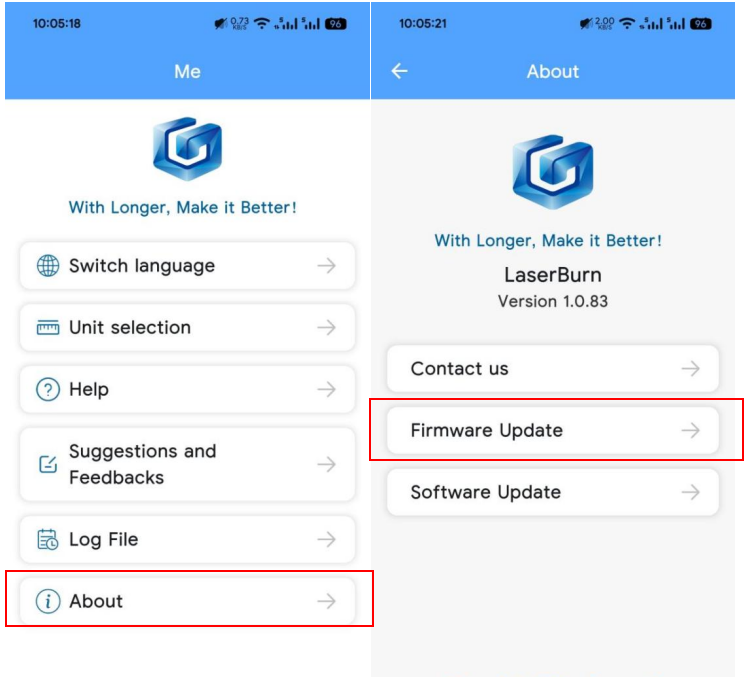

Don't overlook your laser engraver's needs! Regular maintenance is the hidden gem behind its smooth operation and exceptional outcomes. By investing a little time and care, you'll ensure countless fruitful projects with your trusty companion. Have a schedule for cleaning the mirrors and lens regularly and be on the lookout for moving parts and signs of wear and tear. Also, boost the machine's efficiency and functionality by updating the software regularly.

Inspiring Ideas for Your Next Project

Our ring and jewelry engravers enable artists to express themselves in many ways on their pieces without any limitation. They enable them to add a personal touch on jewelry with special quotes or dates. Such jewelry pieces always hold more value to the loved one.

You can also engrave on diverse materials to add depth and texture to your designs. For instance, to get a unique look, try engraving on wood and acrylic or combine metals to achieve a mixed-media effect. The flexibility of our jewelry engraving equipment will enable you to do more than you could with conventional methods of jewelry design.

The Future of Jewelry Engraving with Longer

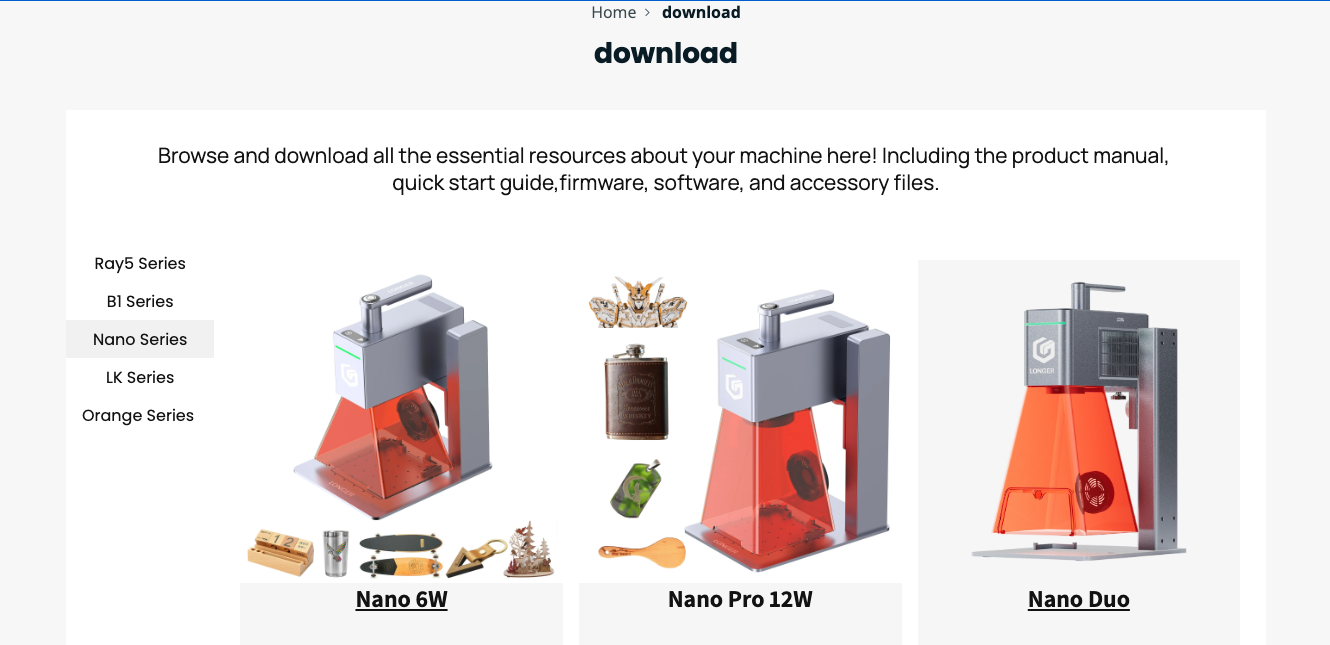

As we focus on the future, we are dedicated to unearthing new possibilities in jewelry engraving. We are engaging in numerous researches and developmental efforts that will enable us to add advanced features and capabilities to our jewelry engravers, so that we continue keeping up with new inventions and technologies.

We are also working to ensure the laser engravers not only personalize jewelry but also enable artists and makers to create unimaginable intricate and multi-dimensional designs. The continuing advancements in laser technology are also enabling us to provide greater versatiliy and enhanced precision.

At the moment, we are looking for an effective way of incorporating machine learning and AI into our laser engravers in order to revolutionize the way designs can be executed and created. This integration could unveil new methods for predictive maintenance, intuitive interfaces, and automated design generation.

At Longer, we are impressed about jewelry engraving's bright future and our part in making it better. We will always ensure our clients have the best equipment for tailoring their jewelry.

In Conclusion

We have unearthed the remarkable potential of our laser engravers in improving jewelry making. Our machines come with every feature required to make magnificent pieces such as user friendliness, versatility, and accuracy. They make crafting jewelry with complicated patterns and designs easier.

While using our machines, you have the liberty of engraving diverse designs and patterns on different materials to maximize their potential. Your skill level in engraving won't limit your creative potential if you choose our laser engravers.

Therefore, we take this chance to invite you to actively participate in our adventure towards making top-tier tailored jewelry. As long as you partner with Longer, you will discover that the only limitation is your imagination.