Products

Trending searches

Carrello ($0)

Carrello ($0)

ABSTRACT

This article introduces the techniques for engraving grayscale images on black anodized aluminum plates using RAY5 series laser engraving machines (taking RAY5 10W as an example). The article mainly explains the three aspects of parameter setting, image mode selection and image attribute adjustment. Through detailed parameter configuration (such as speed, power, line spacing, scanning angle, etc.) and image mode (Grayscale mode is recommended), combined with appropriate image brightness, contrast and Gamma value adjustment, you can obtain a detailed and clear engraving effect.

1. Parameter setting and image mode selection

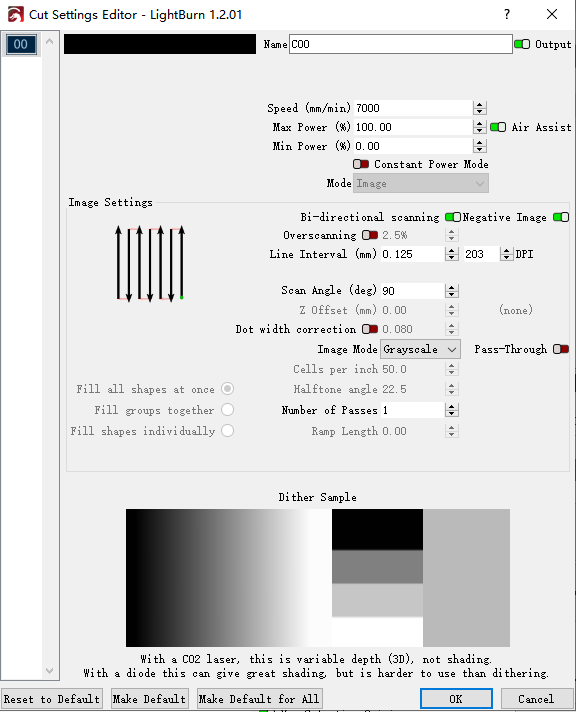

The grayscale engraving effect is closely related to its parameter configuration, so you need to double-click the layer setting in the Cut / Layers interface in Lightburn to open the Cut settings editor. For the RAY5 10W machine, the speed is set to 7000mm/min, the maximum power is set to 100%, the minimum power is 0%, the Line interval is set to 0.125mm or DPI is 203, and the Scan angle is set to 90° (other machine parameters need to be adjusted appropriately according to the parameter table. For the RAY5 5W machine, the Scan angle is recommended to be 0°). Since black anodized aluminum engraving is a transformation from black to white, you need to select Negative image.

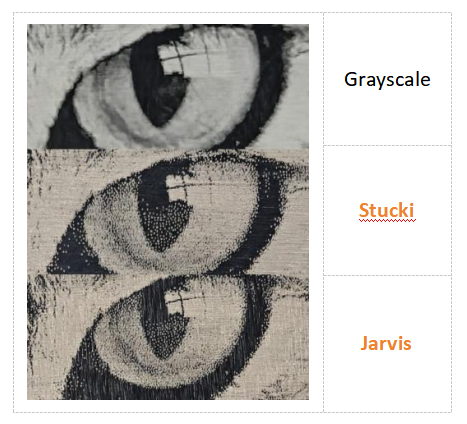

In LightBurn, there are multiple image modes such as Grayscale, Stucki, and Jarvis. The engraving effects of different image modes are compared, as shown in the figure below. Grayscale has smooth shadow transitions and richer details compared to other engraving modes, so it is recommended to use Grayscale mode for engraving.

Grayscale

Stucki

Jarvis

2.Set image properties

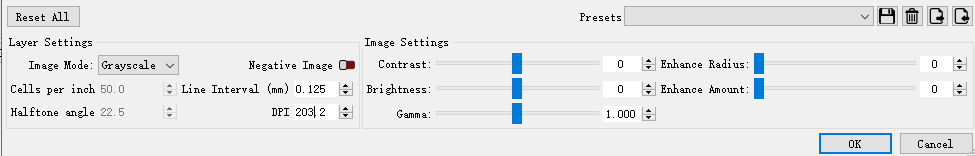

Image contrast and brightness parameters have a direct impact on the final engraving effect. Select the engraved image in Lightburn, right-click and select Adjust image to enter the image parameter adjustment interface, as shown in the figure below.

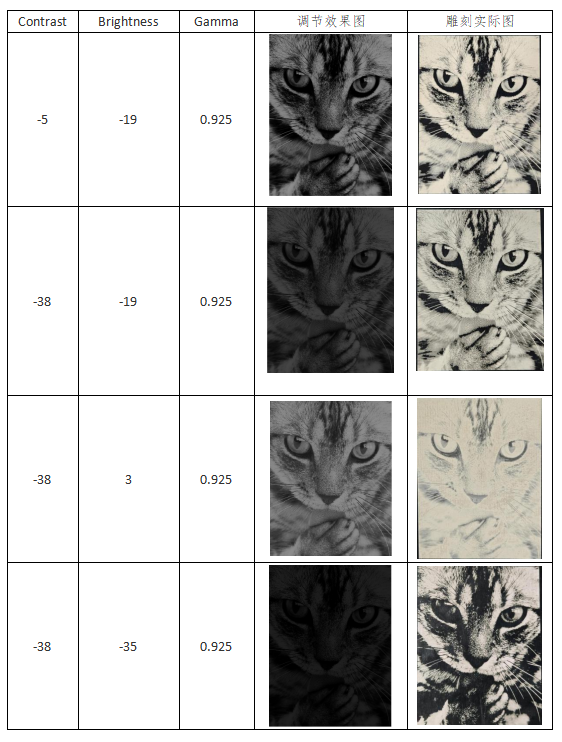

By comparing different parameters with the actual engraving effect, as shown in the figure below, it is recommended that the contrast should not be too high, as too high contrast can easily cause loss of details; when adjusting the brightness, the image should not be completely white or completely black. After comparison, the test image has the best engraving effect when the contrast, brightness and Gama values are set to -38, -19 and 0.925 respectively (the settings of different images are different and need to be adjusted according to the actual engraving effect).

Conclusion

RAY5 series laser engraving machines have the advantages of large format and stable performance, and can present rich grayscale details on black anodized aluminum plates. To achieve the best engraving effect, Grayscale mode should be used first, and cutting parameters should be adjusted according to the machine parameter table. The loss of details can be avoided by appropriately reducing the contrast, brightness and fine-tuning the Gamma value. Although the above parameters are general recommendations, they still need to be fine-tuned in combination with different image materials in actual applications to achieve the best engraving quality.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!