CONTENTS

Trending searches

Wagen ($0)

Wagen ($0)

Calibration:

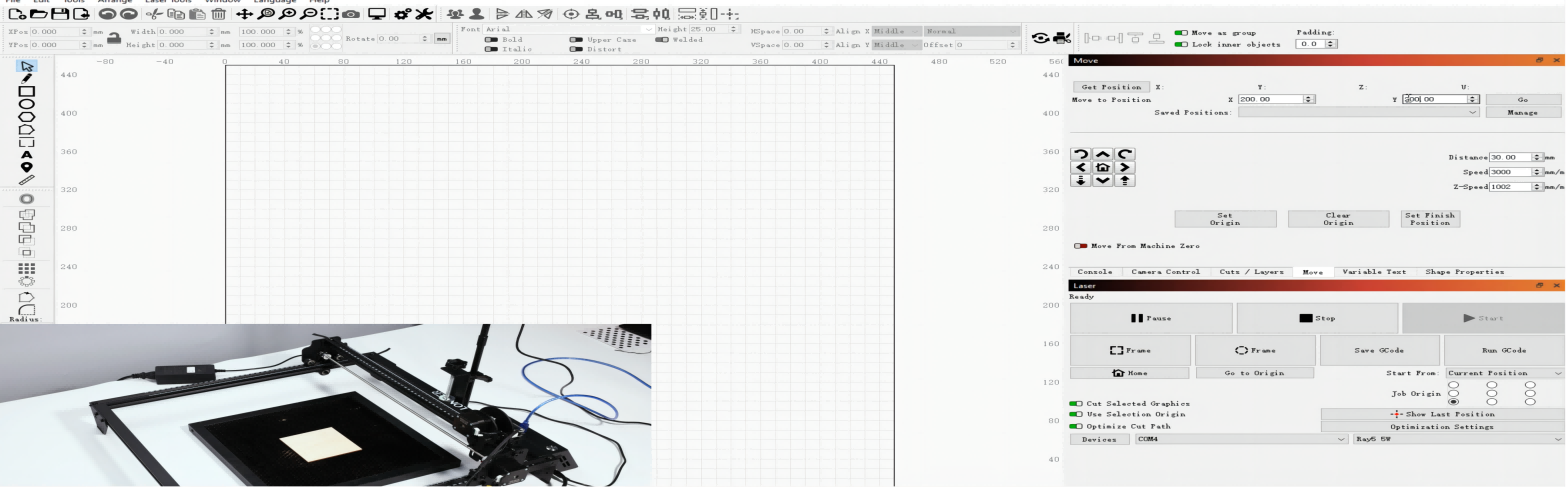

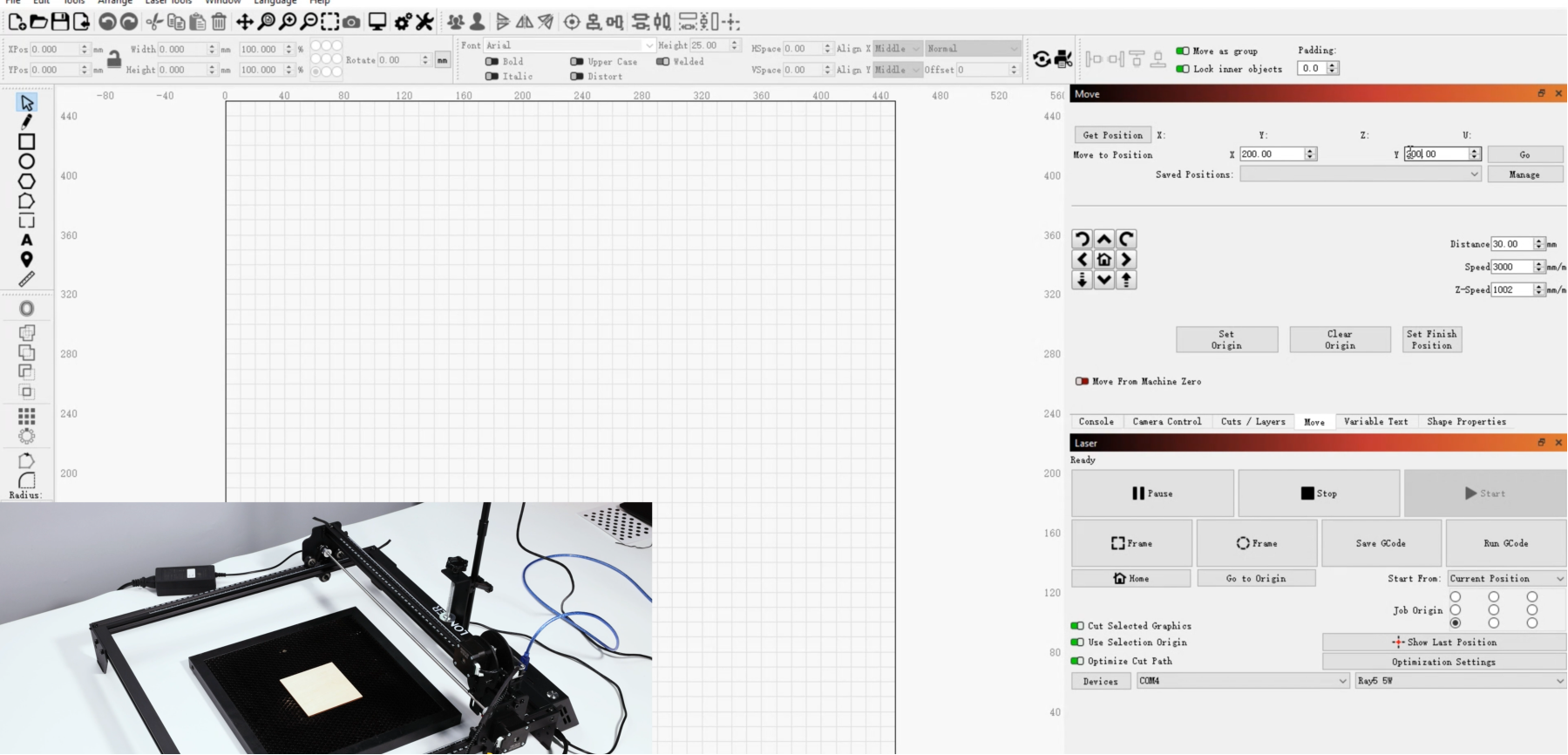

Properly calibrating your laser cutting equipment is paramount to achieving optimal performance. This involves fine-tuning the precision of the cutting bed, directing the beam accurately, and ensuring proper alignment. Consistent calibration throughout the cutting process is key to maintaining accuracy.

For example, with the LONGER laser, precise calibration ensures that the laser cuts through materials effortlessly, producing clean and accurate results every time. The fixed focus feature allows for consistent cutting depth, minimizing the need for manual adjustments.

Material Selection:

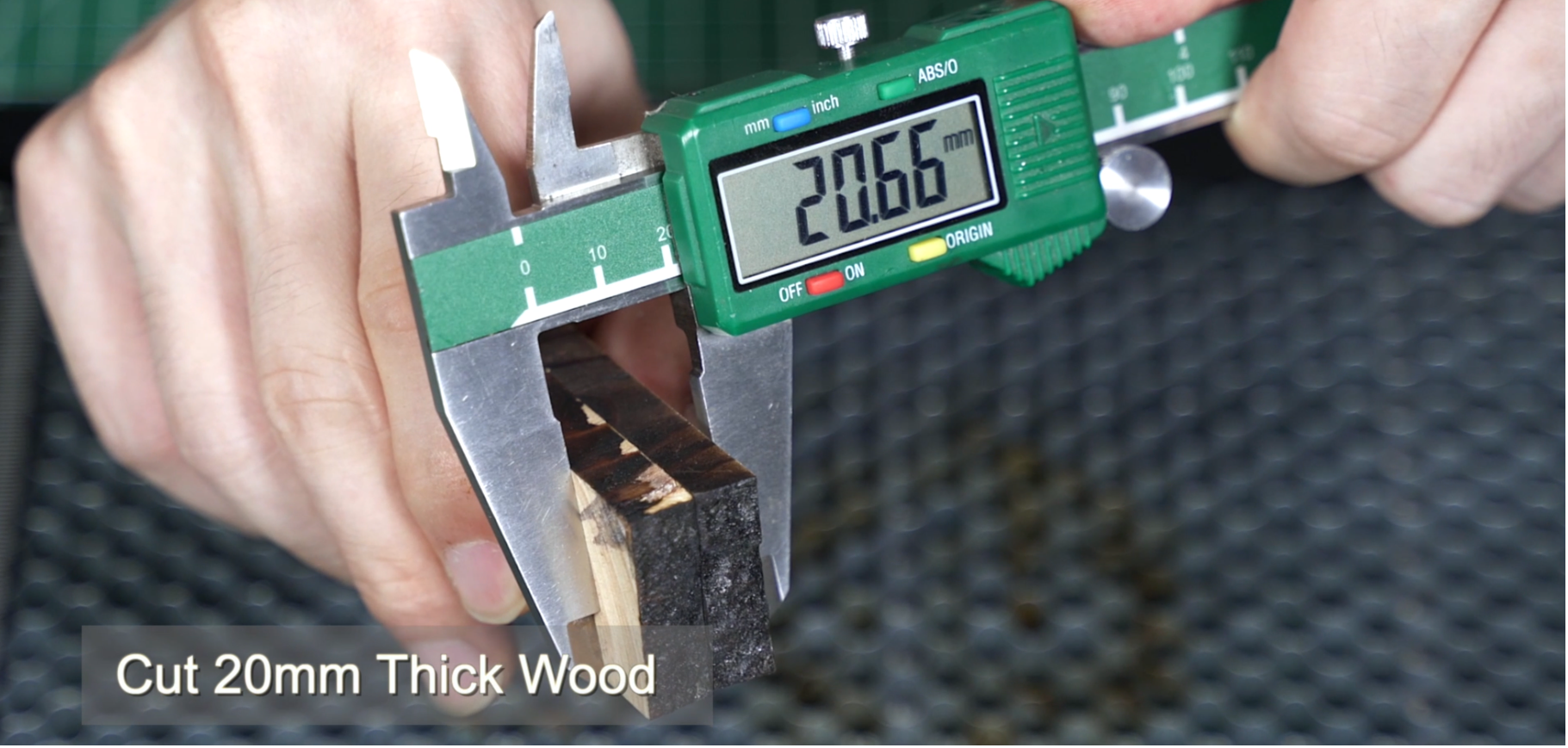

Different materials react differently to laser cutting. Understanding the properties of the material being cut, such as thickness, density, and reflective properties, is crucial for identifying the right settings for the laser. This knowledge enables you to adjust parameters for optimal cutting results.

For instance, when cutting delicate materials like paper or fabric, the adjustable power settings allow for precise control over the cutting process, preventing scorching or burning. On the other hand, the LONGER Laser's rapid speed and high precision make it ideal for cutting through thicker materials like wood or acrylic with ease.

Test Cuts:

Before embarking on engraving complex or intricate designs, conduct test cuts on a spare piece of similar material. This allows you to fine-tune the power, speed, and focus of the laser to achieve the desired effects. Testing also helps uncover any limitations associated with certain materials or potential issues.

For example, when using the Ray5 20W to engrave detailed designs on metal surfaces, conducting test cuts helps determine the optimal power and speed settings to avoid warping or discoloration. Similarly, the LaserB1 30W's ability to cut through thick materials like basswood or acrylic is tested through trial cuts to ensure clean and precise results.

Ventilation:

Laser cutting generates smoke and fumes that can be harmful to health and impact machine performance. Ensure proper ventilation in your workspace or use an exhaust system to remove fumes and maintain air quality.

Secure Material Placement:

To prevent material movement during cutting, securely fasten it to the work table. Unwanted vibrations or shifts can result in inaccurate cuts and affect the quality of the final products. Utilize clamps, double-sided tapes, or fixtures for specialty purposes to keep materials in place.

Tailor Cutting Parameters:

Adjusting power, speed, and frequency settings for the laser can significantly impact cutting accuracy. Experiment with different combinations to find the optimal balance between efficiency and quality. Fine-tune parameters to minimize charring, melting, or burn scars on the material.

Lens Maintenance:

Regular maintenance and cleaning of the laser lens are essential to preserve cutting precision and beam quality. Accumulated residues and debris can degrade performance over time. Follow manufacturer-recommended cleaning techniques and inspect the lens for signs of deterioration or damage, replacing it as needed.

Assistive Technologies:

Consider incorporating camera systems or software functions that offer real-time monitoring and alignment assistance. These tools enhance accuracy and speed up operations, particularly when cutting intricate designs or complex geometries.

In Conclusion

By adhering to these essential tips and harnessing the capabilities of your LONGER laser engraving, you can attain unparalleled precision and efficiency in your cutting and engraving endeavors, irrespective of the complexity or material involved. With LONGER's expertise garnered from eight years of dedicated research in laser technology, rest assured that you're equipped with the LONGER's laser to elevate your projects to new heights.

RELATED POSTS

Program

Company

Visit

(+1) 888-575-9099

Customer Service: support@longer.net

Brand Cooperation: info@longer.net

!