3D modeling significantly impacts vital industries such as medicine, sports, aeronautics, etc. But is also beloved by enthusiasts and hobbyists. Printing them has been made relatively easy if you already have a working digital 3D design of any model. This ease of operation has made consumer flock to buy 3D printers. Are you considering buying a 3D printer yourself but are worried about the high costs and complexity of designing?

Well, now you don’t have to worry as today we have chosen an affordable but professional brand, LONGER, explained in this article. Let’s start!

Defining Features of LONGER 3D Printers

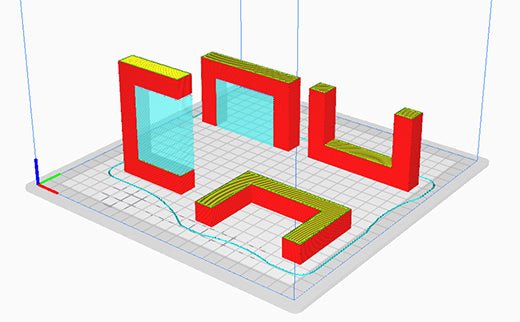

This section will discuss some of the defining features of each 3D printer in this list. It will be followed by the significant differences between each and which is best for you. All these printers are open-source coded, allowing consumers to share their best designs with the community while taking inspiration from others for the best results.

1. LK4 X FDM 3D Printer

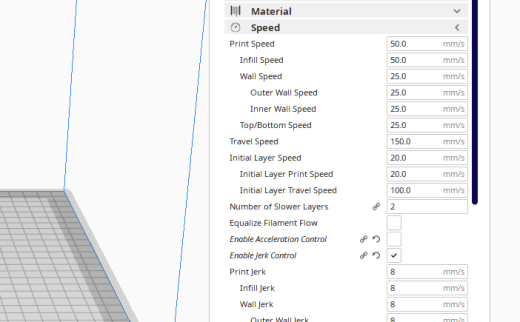

LK4 X comes with a 4.3” colored touchscreen helping you choose the best designs and make efficient adjustments. Make your ideas come true with its big bed design and several applications, especially for teaching kids in STEM and other art and design projects.

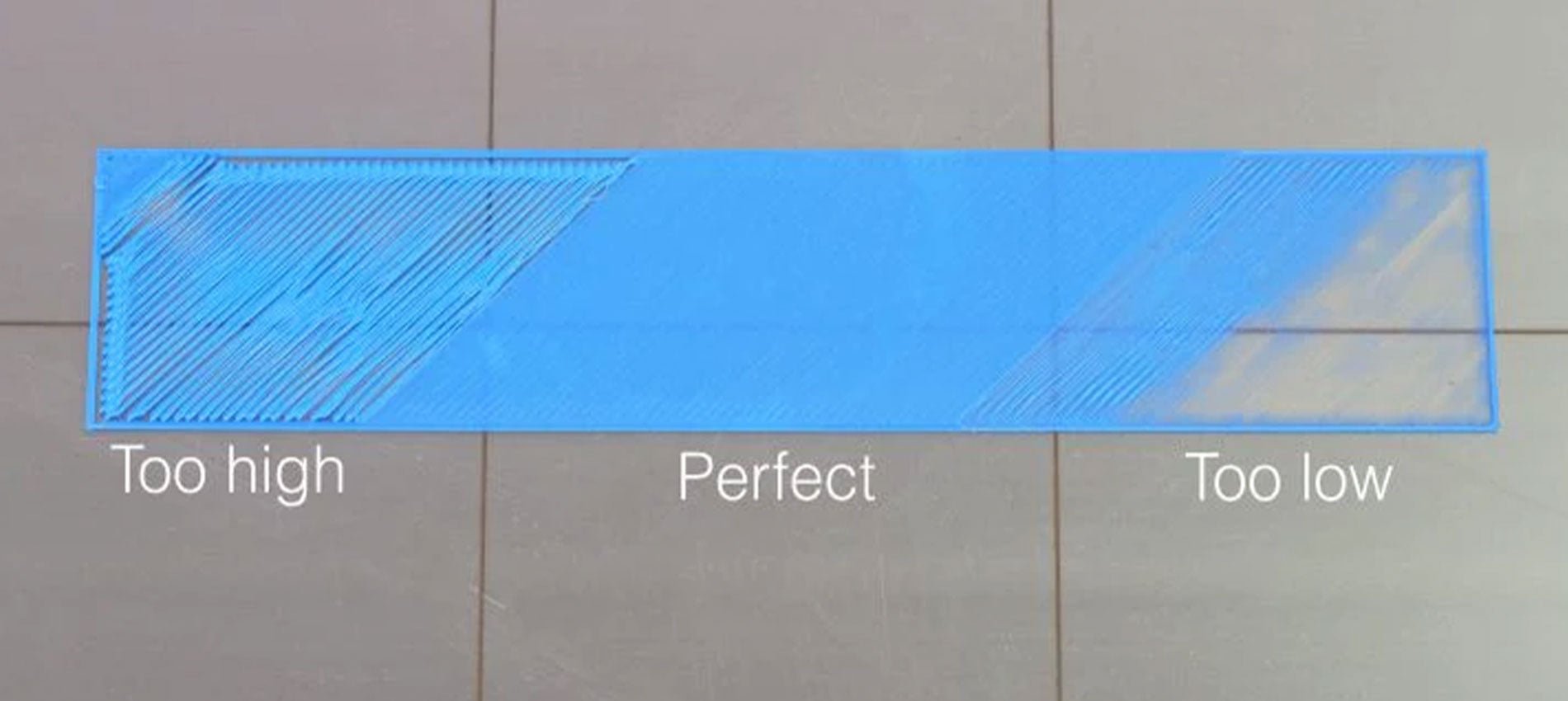

The LK4 X has intelligent 16-point auto leveling supporting your intricate projects, compensating for any unevenness. You get stronger and more accurate filament control with a double-gear extrusion mechanism and direct drive chip. This feature is further enhanced by the premium spring-flexible steel that allows staying power for the adhesion with the printed model.

- Uses innovative auto-leveling technology to compensate for the unevenness of the hotbed

- Has building size of 8.66"*8.66"*9.84" (220*220*250mm)

- Comes with a 32-bit open-source motherboard, a 4.3-inch touchscreen, and a flexible PEI film

- It comes pre-assembled with 95%

- Fast shipping available

- Order today for only $299.99

Consumer Comments

GWS 1205 – At first, I rated it below 3, but eventually discovered that the problem was the misalignment of the z-axes after doing a vast amount of research and watching YouTube videos. After I tuned it in, the machine is now operating perfectly.

2. LK5 PRO FDM 3D Printer

LK5 Pro has the upgraded Dual Blower kit that cools the filament as the material is being extruded, saving you the trouble of any deformation. The triangle design-build allows you to make stable and perfect projects as it has minimal vibration while working.

This model is for you when it comes to quieter and more enhanced printing due to High Temp resistance tubing.

- Has exceptional building size of 300x300x400mm (11.8"x11.8"x15.7")

- Best for high-precision 3D printing

- Comes with pre-installed 3 TMC2208 ultra-silent chipsets, which are based on open-source coding, making them ultra-quiet

- Has a Carborundum glass platform for easier mold taking

- Comes with run protection

- Excellent price of only $299.99

Consumer Comments

- Vantlin –I've just started using 3D printing. I searched for a high-quality printer at a fair price because this was my first foray into 3D printing. I made the right choice by purchasing the LONGER LK 5 Pro!

3. LK4 PRO FDM 3D Printer

The LK4 Pro FDM 3D printing machine has a modest build, a cute form, a new metal frame, a trendy, modern look, a self-developed intelligent system software, a fresh user interface, and standalone manufacturing. It is a popular and inexpensive 3D printer type.

The LK4 printer makes a beautiful present for the creative person in your family, the aspiring designer, or the young person getting ready to enroll in their first technology course.

- Open-source codes

- Ultra-quiet and no noise enhances the functionality if you are printing at home.

- Equipped with a 4.3” touch screen for convenient controlling

- Enhanced structural rigidity with new Aluminum frame design

- Built-in Safe Power Supply for efficient power usage

- Fast shipping available for the purchase of only $179.99

Consumer Comments

- Benckert –After the wait for the new touchscreen and the software update, the printer appears to be operating as intended. I have no experience with 3D printing, but after viewing a few Youtube clips about the technology in general and Cura in particular, I am off to a good, trouble-free start. The printer is finally functioning as described, though I intend to add Octopi for further monitoring and control features.

4. Orange 4K Resin 3D Printer

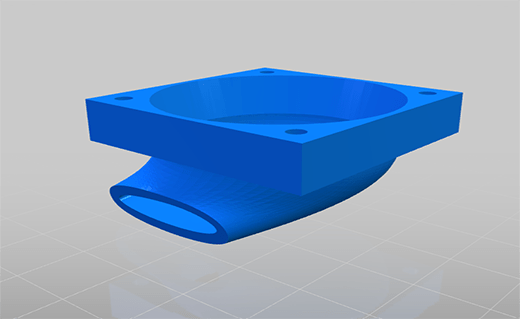

LONGER Orange 4K is the leader in Subpixel technology that can make precision models for up to 4K resolution providing more detail in miniature designs. The in-house slicing software is top of the line that is not just easy to operate, but the slicing feature is three times faster. What more can you want with a 3D printer having minute-level details in a small design?

There are tons of 3D printing applications, such as making toys for kids, allowing designs for manufacturing concerns, perfect dental models, and even ultra-detailed architecture designs.

- Subpixel technology with a fantastic resolution of X 31.5µm Y 10.5µm will give you the best results if you love printing miniatures.

- Comes with 6480*3840 Resolution, Parallel UV Lighting Sources, and Fast Printing Mono LCD Screen

- Its four crews make leveling much easier.

- Features temperature detecting tool for LONGER life span

- Fastest printing with less exposure time

- You can purchase the 3D printer today for only $319.99

Consumer Comments

Heath2015 – I've only recently started using this incredible equipment for 3D printing, but I have to admit it does a good job. Even though I had rarely printed anything before, I quickly and easily had the LONGER Orange 30 running in no time.

What are the Biggest Differences among LONGER 3D Printer Models?

The LK4 X model offers sophisticated 16-point accurate levelling for stable working settings when the base plate needs to move, and it is priced the same as the LK5 Pro model. The inclusion of double-gear extrusion for larger and more complex structures distinguishes the LK4 X from competing versions. Finally, even though all 4 versions can have their essential components upgraded, the LK4 X has the most possibilities, making it an excellent modular machine.

Contrastingly, LK5 PRO comes with a triangular design and dual inclined road, which assists in producing optimal printing results. It also comes in handy in eliminating the turbulence and retention of the Z-axis. Its 3Kits TMC2208 for XYZ Axis and larger bed size add to its value.

Coming to LK4 Pro, although this model is similar to the LK4 X and LK5 Pro, its ultra-durable aluminum manufacturing sets it apart from others. Moreover, it has a built-in Safe Power Supply that keeps your machine and investment safe. In our opinion, LK4 Pro is the second largest of the 4 right after LK5 Pro, a great comprise between LK4 X and LK5 Pro.

Orange 4k is your best bet if you want to make small yet intricate designs. It comes equipped with Subpixel technology that distinguishes it from other competitors. No matter if it’s the smallest, it costs the most.

Comparison Chart of LK4 X vs. LK5 Pro vs. LK4 Pro vs. Orange 4k

Please see the following table to understand what each of these printers has for you.

|

Model Number |

LK4 X |

LK5 Pro |

LK4 Pro |

Orange 4k |

|

Printing Technology |

FDM 3D Printing Technology |

FDM 3D Printing Technology |

FDM 3D Printing Technology |

LCD Stereo lithography |

|

Working Area |

220*220*250mm(8.66"x8.66"x9.84") |

300*300*400mm (11.81"*11.81"*15.75") |

220*220*250mm (8.7"*8.7"*9.8") |

120*68*190mm (4.7"*2.7"*7.48") |

|

Printing speed |

≤180mm/s |

≤180mm/s |

≦180mm/s (Suggest 60-80mm/s) |

Up to 80mm/h on Mono Version |

|

Printing accuracy |

±0.1mm |

±0.1mm |

- |

10 micrometer |

|

Layer thickness |

0.1-0.4mm |

0.1-0.4mm |

0.1-0.4mm |

0.01-0.1mm |

|

Support filaments |

PLA/TPU/ABS/ PETG/Wood |

PLA/ABS/ PETG |

1.75mm PLA/ABS/PETG |

|

|

Direct drive extruder |

Direct drive extruder |

Bowden Extruder |

- |

- |

|

Auto leveling |

Yes |

Optional |

|

- |

|

Filament Detector |

Yes |

Yes |

Yes |

- |

|

Resume Printing |

Yes |

Yes |

Yes |

- |

|

Hotbed |

PEI Flexible Steel |

Ceramic Coated Glass |

|

- |

|

Motherboard |

32-Bit Open Source & Silent Motherboard |

8-Bit Open Source & Silent Motherboard |

|

|

|

Connection method |

TF card or USB |

TF card or USB |

TF card or USB |

USB |

|

Hot bed Temperature |

≤100°C |

≤100°C |

|

|

|

Nozzle Temperature |

≤250°C |

≤250°C |

190-250℃ |

- |

|

Rated power |

320W |

350W |

|

- |

|

Gross Weight |

9.78KG |

13.5KGS |

8.5KGS |

11.5KGS |

|

Printer Dimension |

485*465*615mm |

580*540*663mm |

425*402*505mm |

230*230*437mm (9.16"*9.06"*17.02") |

|

Package Dimension |

540*525*265mm |

662*588*193mm |

467*412*187mm |

310*310*580mm (12.2"*12.2"*22.83") |

|

Nozzle Diameter |

|

0.4mm |

0.4mm |

|

|

Slice Software |

- |

Cura, Reptier-Host |

Cura, Reptier-Host |

Longerware / Chitubox / Lychee |

|

File Format |

- |

STL, G-Code. OBJ |

G-code, STL |

- |

|

LCD Screen Size |

- |

4.3 Inch |

- |

5.5 Inch |

|

Salient Features |

· More Height · Intelligent Auto Levelling · 5:1 reduction ratio · Ultra silent motherboard · Fast and quiet printing |

· Affordable printer · Triangle design · Silent printing · Glass upgrade for easy removal · High Temp resistant tubing |

· Amazing tempered glass design · The printing recovery function is available · Ultra quiet mode · Durable aluminum frame design · Safety in power supply |

· Subpixel technology · Ultrafine precision · Quick printing with mono screen · Parallel UV Lighting Sources · Dual Z-Axis Design |

|

Price |

$299.99 |

$299.99 |

$179.99 |

$319.99 |

Conclusion

That was all about the four amazing printers from the renowned printer manufacturing brand, i.e., LONGER. Hope you find it helpful in making an informed decision about which one you should get.

https://www.longer3d.com/products/lk5-pro-fdm-3d-printer