Exploring the Principle, Development, and Applications of Infrared Lasers

Infrared lasers, as crucial optical devices, play a significant role in modern technology. They find wide-ranging applications in fields such as communication, medicine, and military, while also serving as essential tools in scientific research. Harnessing the power of infrared lasers, Longer has been at the forefront of laser engraving technology for many years.

With a rich history of laser research 8 years since 2016, Longer has continuously pushed the boundaries of innovation to develop a diverse range of precision laser engraving machines. From desktop-grade models to industrial-grade solutions, each Longer laser engraver represents the culmination of years of research, development, and expertise.

As pioneers in the industry, Longer has introduced numerous groundbreaking products, each meticulously designed to meet the evolving needs of users across various sectors. Whether it's the high-speed engraving capabilities of the RAY5 series or the advanced cutting technology of the B1 series, Longer's laser engraving machines have earned acclaim for their exceptional performance and reliability.

1.Principle

Stimulated Emission: In infrared lasers, atoms or molecules in the active medium (usually a specific solid, gas, or semiconductor material) are in an excited state. When a photon (i.e., an incident photon) collides and interacts with an atom or molecule in an excited state, they can induce the atom or molecule to retreat from the excited state to the ground state, releasing a photon of the same frequency and phase as the incident photon. This released photon has the same direction, frequency, and phase as the incident photon, a process called stimulated emission of radiation. This forms the amplification of photons, thereby producing laser light.

Optical Resonance: Infrared lasers usually consist of an optical cavity composed of two mirrors. One of the mirrors is fully reflective and the other is partially transparent. Incident light is reflected by the mirror and propagates back and forth within the optical cavity, where it interacts with atoms or molecules in the active medium. Only light that matches the resonant frequency of the optical cavity is amplified, while the rest is filtered out. This process of frequency-selective amplification is called optical resonance. By continuously adjusting the length of the optical cavity or using optical gain media, laser output at specific wavelengths can be achieved.

- Development

- Early experiments (1960s):

In the 1960s, infrared laser research focused mainly on gas and solid lasers. The earliest infrared lasers used gas as the activation medium, such as carbon oxide lasers and silicon oxide lasers. Although these early lasers made some progress, their applications were limited due to problems such as large size, high energy consumption, and expensive manufacturing costs.

- The rise of semiconductor lasers (1970s to 1980s):

With the development of semiconductor technology, infrared semiconductor lasers have gradually become a research hotspot. Compared with traditional gas and solid-state lasers, infrared semiconductor lasers have the advantages of small size, high efficiency and low cost. This has led to wider applications of infrared lasers, especially in communications and medicine.

- Technological progress and application expansion (1990s to present):

With the continuous advancement and innovation of technology, the performance of infrared lasers has been further improved. In the field of communications, infrared lasers have become the core component of optical fiber communication systems, achieving high-speed and high-bandwidth data transmission. In the medical field, infrared lasers are widely used in laser surgery, medical imaging and diagnosis, providing new methods and tools for the treatment and diagnosis of diseases. At the same time, in the military field, infrared lasers play an important role in guidance systems, target identification, and reconnaissance, improving the accuracy and effectiveness of military equipment.

- Application

Infrared lasers have a wide range of applications in various fields, and their high energy density, narrow beam width and tunability make them a core component in many technologies and industries. Here are some of the main application areas of infrared lasers:

Communication: Infrared lasers play a vital role in optical communication systems. They are used as light sources, optical amplifiers and optical modulators in optical fiber communication systems to achieve high-speed, high-bandwidth data transmission. Infrared lasers are also widely used in wireless communication systems, such as infrared remote controls and infrared data transmission equipment.

Medicine: In the medical field, infrared lasers are widely used in laser surgery, medical imaging, and diagnostics. For example, they are used in laser treatment of retinal diseases, cataract surgery, and skin plastic surgery. In addition, infrared lasers are used in medical imaging technologies such as optical coherence tomography (OCT) and infrared thermography to diagnose and monitor diseases.

Military: In the military field, infrared lasers are widely used in guidance systems, target identification and reconnaissance. They are used to guide guided missiles and precision strike weapons, improving the accuracy and combat effectiveness of military equipment. Infrared lasers are also used in infrared thermal imaging and night vision technology to detect, identify and track targets.

Scientific research: Infrared lasers play an important role in scientific research and are used in spectroscopy, atomic physics, and chemical dynamics studies. They are used to prepare infrared spectrometers, laser measurement instruments and optical experimental equipment, providing scientists with important tools for studying the properties and interactions of matter.

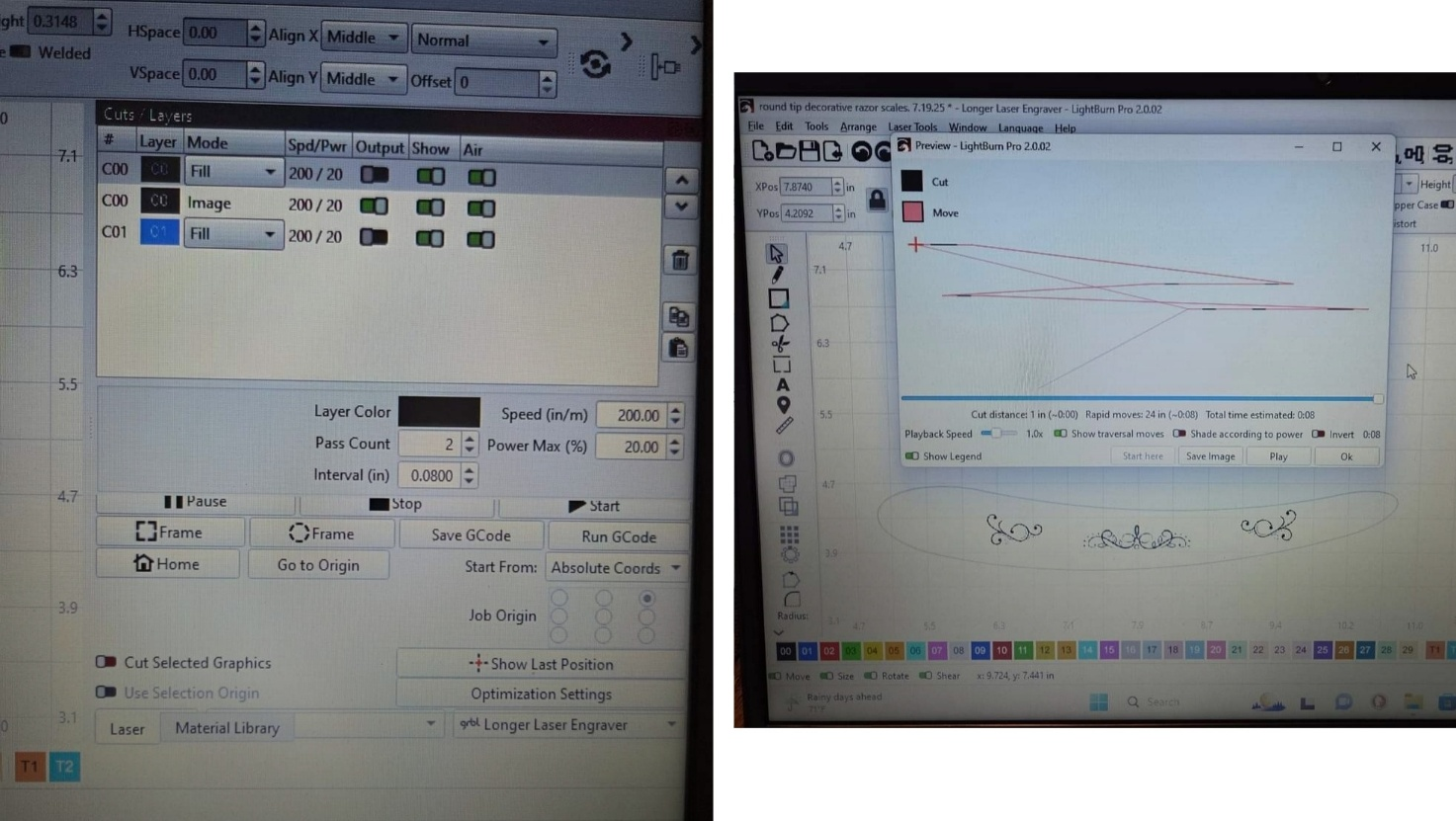

Industry and Materials Processing: Infrared lasers also have a wide range of applications in industry and materials processing. They are used in processes such as cutting, welding, drilling and surface treatment, and are used to process materials such as metal, plastic, glass and ceramics, improving production efficiency and product quality.

4.Conclusion

The principle, development, and applications of infrared lasers underscore their paramount importance in modern technology. LONGER's comprehensive understanding of optical sciences and its formidable research and development capabilities have positioned the company at the forefront of laser technology. Through meticulous research and innovation, LONGER has mastered the intricate principles governing infrared lasers, enabling the development of cutting-edge laser engraving machines that set new standards for precision and performance. LONGER's relentless pursuit of excellence and its unwavering commitment to technological advancement have propelled the company to the forefront of the industry.

As technological advancements continue to reshape the landscape of modern society, infrared lasers will remain indispensable tools in driving innovation and progress across various scientific and technological fields. LONGER's expertise in harnessing the power of infrared lasers not only drives the development of its own products but also contributes to the advancement of the broader technological ecosystem.

With a keen focus on research and development, LONGER continues to push the boundaries of what is possible with infrared laser technology. By leveraging its expertise and resources, LONGER is poised to unlock new opportunities and drive innovation in scientific and technological fields for years to come. As the demand for advanced laser technology continues to grow, LONGER remains committed to delivering cutting-edge solutions that empower users to achieve their goals and drive progress in their respective industries. With its unparalleled expertise and commitment to innovation, LONGER is poised to shape the future of laser technology and revolutionize the way we interact with the world around us.