When we talk about FDM 3D Printing as a whole, the question that troubles most people is whether these printers are practical enough to be used for real-world operations. To tackle these concerns, we'll be looking at what FDM 3D printing is and whether or not it's suitable for your business, in particular.

What is FDM 3D Printing?

Fused Deposition Modeling is a process that involves heating up the filament and depositing it in layers on a build platform. This process allows for the creation of complex shapes and structures with high accuracy and detail. FDM 3D printing can be used for a variety of applications ranging from prototyping to product manufacturing.

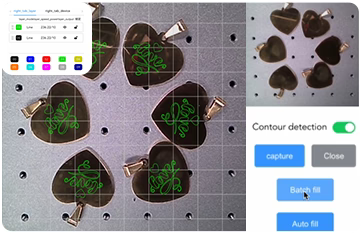

FDM 3D printing can be used to create parts for prototypes, end-use products, or even customized items such as jewelry or toys. With the help of this technology, businesses are able to reduce their production costs while creating high-quality products with greater efficiency.

What are the Differences between FDM Printing and SLA Printing?

3D printing technology has revolutionized the way products are designed and manufactured. Two of the most popular 3D printing technologies used today are FDM printing and SLA printing. While both technologies have their advantages and disadvantages, it is not easy to determine which one is better for a particular application.

Fused Deposition Modeling (FDM 3D Printing) involves melting a plastic filament material through a heated nozzle and then depositing it in layers to build up an object. This type of 3D printing is fast, cost-effective, and can be used to produce complex shapes with high accuracy.

It is being used in a wide range of industries, such as automotive, aerospace, medical, consumer goods, and many more. With its increasing popularity, FDM 3D printing is becoming one of the most popular ways to create customized parts or objects quickly and efficiently.

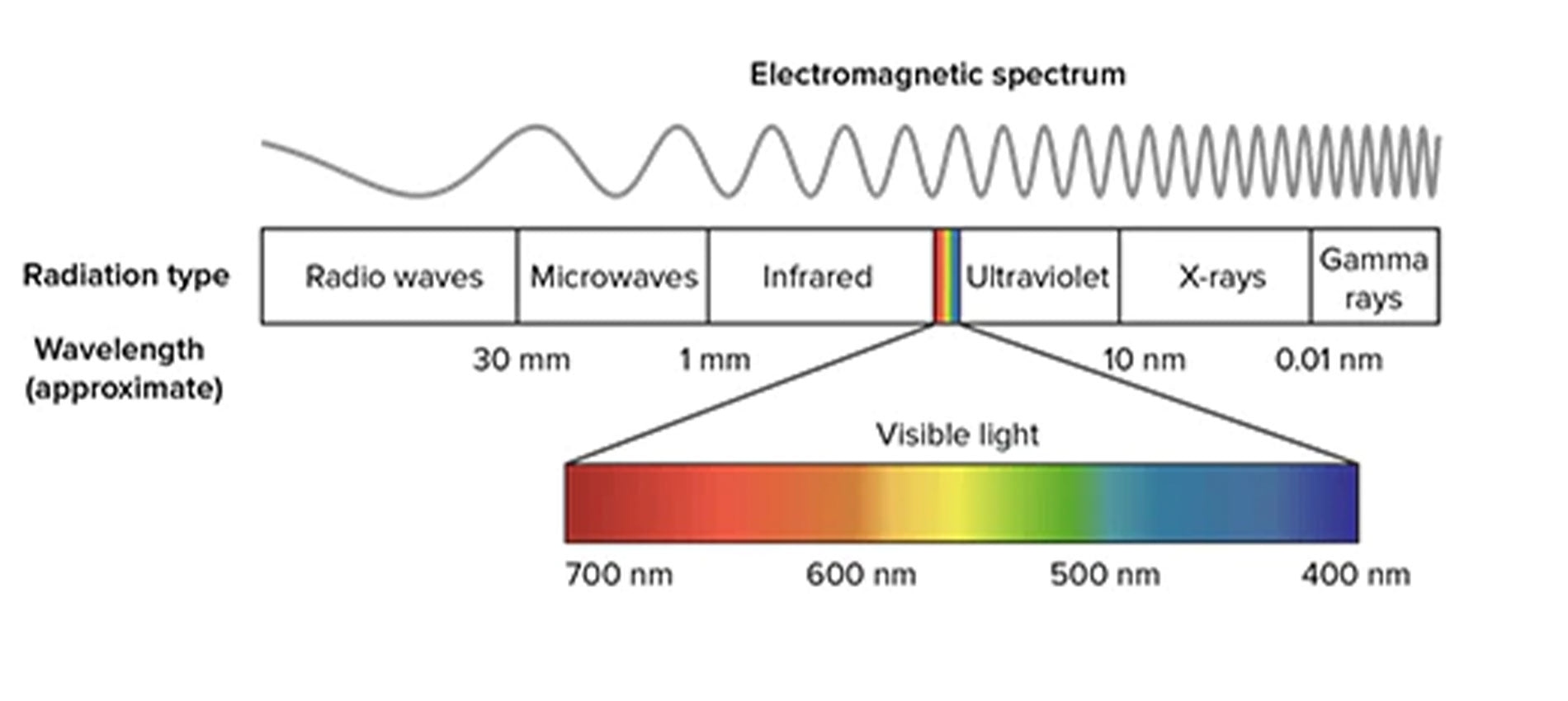

On the contrary, SLA 3D printing is a revolutionary technology that has changed the way we produce products. It is a type of 3D printing process that uses a laser to cure liquid resin layer by layer, creating complex and detailed objects with high accuracy and surface finish.

Although both printing technologies are efficient in working, deciding which one will work best for you depends entirely on what outcome you are expecting.

Is FDM Printing Practical for Real-World Operations?

3D printing technology has completely changed the way we create and manufacture products. It has allowed us to print complex shapes and structures with precision and accuracy, making it a perfect choice for a variety of applications. FDM printing, in particular, is being used more and more in real-world operations due to its cost-effectiveness, speed, and scalability.

This technology has a lot of advantages over other 3D printing methods, such as its low cost and ease of use. However, there are some drawbacks to consider when deciding if FDM printing is right for your operations. The upsides and downsides have been discussed ahead.

The Perks of Utilizing FDM 3D Printing

FDM 3D printing offers a range of benefits for businesses of all sizes, from medium-scale startups to large corporations. The most significant perks of utilizing FDM 3D printing include faster production times, improved product quality, and cost savings. With FDM 3D printing, businesses can quickly create complex designs with intricate detail and accuracy while still keeping costs low.

Additionally, the technology can be used to produce highly customized products that meet specific customer requirements. By leveraging FDM 3D printing, businesses can take advantage of its many benefits and gain a competitive edge in their respective markets.

From cost savings to faster production times, FDM 3D printing can help you streamline your manufacturing process and produce quality products in less time.

The Downsides of Utilizing FDM 3D Printing

FDM 3D printing has become an increasingly popular technology for a variety of uses, from prototyping to end-use parts. While it offers many advantages, there are some downsides that should be taken into consideration when utilizing this technology. These include the high cost of materials, the slow printing speed, and the limited accuracy of parts produced.

But, all these drawbacks are concerned with the expertise of practitioners. If you are a pro in handling the printer, you can do wonders with it. Even beginners can also come up with excellent results, if they go through the detailed how-to guide for using it. Another factor contributing to these drawbacks is the quality of your FDM 3D printer. If you are using one sourced from inexpensive and unreliable manufacturer, you should expect to face these cons.

The Truth about Getting an FDM 3D Printer: Is it Worth It?

With the rise of 3D printing technology, more and more people are turning to FDM 3D printers to create custom objects. But is it actually worth getting one? FDM 3D printers offer a lot of advantages over traditional manufacturing methods, including cost savings, speed, and convenience. FDM 3D printers are now more accessible than ever.

Getting an FDM 3D printer also depends on your individual needs and goals. For example, if you need to make small-scale prototypes or models for your business, then an FDM 3D printer can be a great investment.

Worried About Getting an Effective 3D Printer: Longer May Have Just What You Need

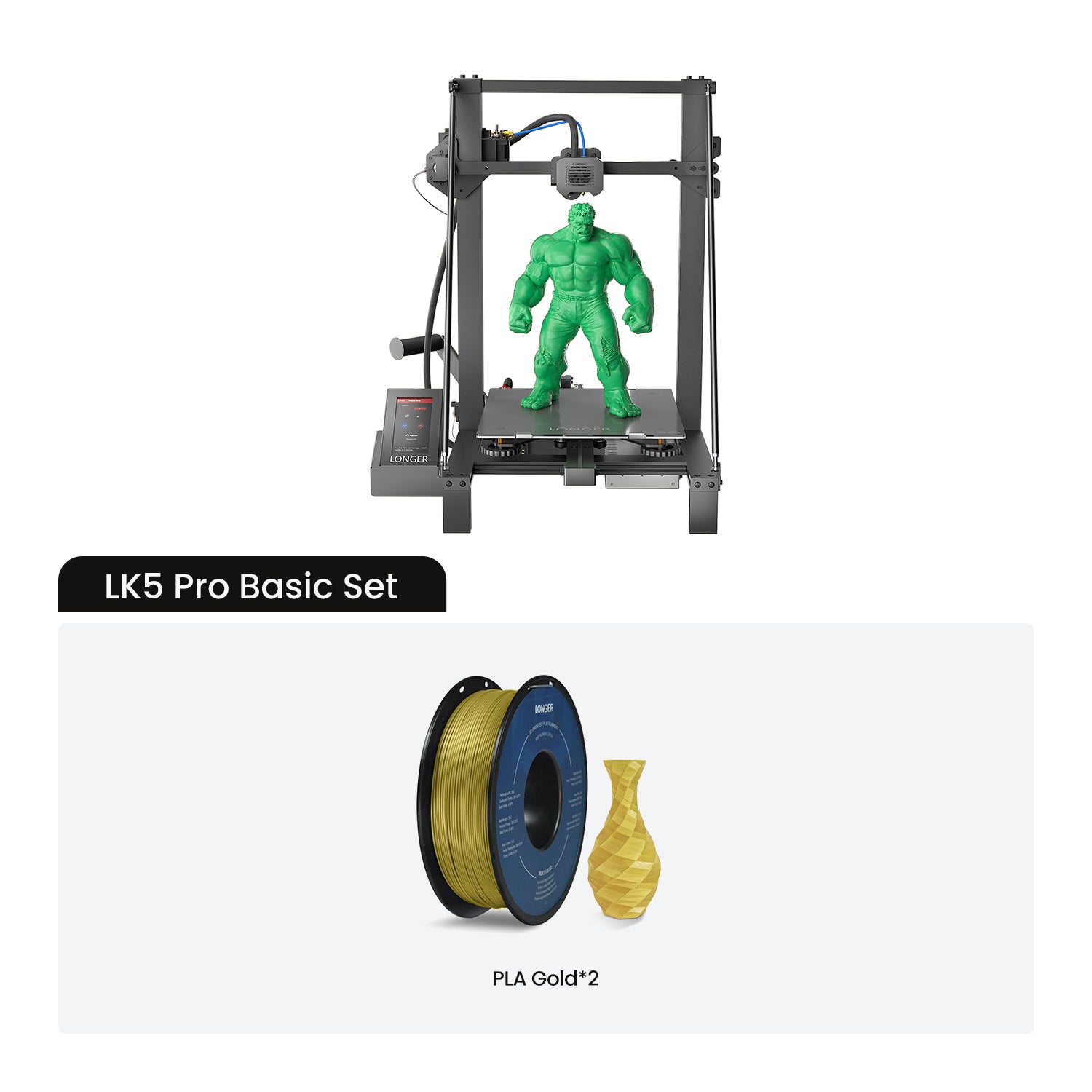

If you're looking for an effective 3D printer that can do the job right, then you need not worry anymore. Longer has just what you need to get your 3D printing projects done quickly and efficiently.

From powerful desktop models to large-scale industrial machines, including FDM 3D Printers and Resin Printers, Longer offers a variety of options that will help bring your ideas to life. Therefore, if you're on the lookout for a dependable FDM 3D printer that won't break the bank, then Longer is the perfect choice for you.

Some of our top picks from their top-notch collection include the FDM 3D Printers, LK5 PRO, LK4 PRO, LK1, etc., and Resin Printers, Orange 4K, Orange 30, and Orange 10.

Conclusion

Ultimately, the decision of whether or not it's worth getting an FDM 3D printer will depend on what kind of projects you plan on using it for. FDM 3D printers offer many advantages over other types of 3D printing technology.

They are affordable, easy to use, and can produce high-quality prints with a variety of materials. They also have a wide range of uses, from prototyping to production parts and even home decor items.

https://www.longer3d.com/products/lk5-pro-fdm-3d-printer